A comparison of features and benefits of an open architecture platform vs. an off-the-shelf solution for Industrial Automation and IoT

In Information Technology it has become almost axiomatic that it’s cheaper to purchase an off-the-shelf solution instead of building your own application from scratch. A custom piece of software can very expensive because it is being built for a single purpose and with one customer in mind. It usually takes much longer to get up and running and to work out all of the bugs. But developing custom software is still embarked upon because it comes with some significant benefits, especially if you are an OEM, interested in reselling the solution.

What if there was a software platform that provided the benefits custom development, but also mitigated the risks of rolling out your own solution, and even dramatically reduced costs over time?

So let’s explore this a bit further, breaking down the pros and cons of both custom development and off-the-shelf products. We’ll then demonstrate how the OAS Platform is unique in the IIoT space and what an open architecture can do for you.

So let’s explore this a bit further, breaking down the pros and cons of both custom development and off-the-shelf products. We’ll then demonstrate how the OAS Platform is unique in the IIoT space and what an open architecture can do for you.

Off-The-Shelf Products

The pros and cons of off-the-shelf (OTS) or “canned solutions”, which may still include some tools for designing HMI screens and logic, but within proprietary environments.

PROS

Rapid configuration

One of the most attractive features is the relative ease at which OTS products can be configured and deployed since the feature set and tools are well-defined.

Built-in tools and applications

In order to speed up and simplify deployment, most OTS products include many tools for creating things like HMIs, and often have full-blown applications ready to be used in production.

Generally well-supported

Coming from many well-established companies, these products usually come with a team of support personnel and documentation, which usually comes at an additional cost.

Great for demos or proofs-of-concept

When an OTS platform is narrowly focused on a solution domain, and when tools and applications are proprietary, these products are impressive during tightly controlled demos. Little or no programming is required to get up and running.

CONS

Difficult (or impossible) to customize

Once you start using these products, you’ll quickly find that you need some functionality that they do not provide within the basic toolset. So then you must resort to using APIs with some custom development to

extend them. Other times, customization is not even possible.

Strict licensing, difficult for OEMs

To protect their intellectual property and branding, software vendors tend to limit OTS platforms by the number of users connected to them, and it can become very expensive and restrictive very quickly for OEMs, making it difficult to fit these products into your business model.

Proprietary data format

Another way license restrictions are enforced is to lock down the data within the system. OTS vendors provide tools for importing or exporting data, but the data is usually stored in a proprietary format.

Proprietary tools and user interfaces

If your requirements are to generate an application with a specific user interface, you may find an OTS solution limiting. Many of them provide a large library of symbols and objects, but your application will

look like many others, and will unlikely include your own company branding. You’re also required to use the vendors tools for configuration and modification.

Specialists are expensive and scarce

OTS vendors generally sell to a niche market, so while the install base and investments may be large, the actual number of individuals with the skills to use the software is a small pool relative to the global software and IT community. Few consultants have the necessary skill to work with each OTS product, and if so, come at a high price even when they are available.

You’re paying for features you don’t need

Most of these products have wide variety of features, but since they’re developed for most situations and not just yours, you end up paying for features you will never use. During an evaluation of an OTS product, the number and depth of features is a selling point, but are rarely ever used in production.

Custom Development

The classic alternative to off-the-shelf products is a fully customized application developed from the ground up. Like a well-tailored suit, this can be the best fit for your needs, but comes with its own challenges. And just like a well-tailored suit, custom software development doesn’t always respond well to size and scope changes.

PROS

Fully Customizable

Since the solution is developed for your specific needs, it can contain any feature you require and nothing else

Open data formats

You can choose your data store, and are not locked into proprietary tools for import/export, or license restrictions on your own data.

Affordable and highly available resources

Choosing your own development languages and tools also means that you can create your custom solution using ubiquitous technologies. Software engineers and consultants are abundantly available at reasonable prices.

No licensing restrictions

If the solution is yours, your only licensing restrictions would come from any contracts established with your development team and any underlying technologies utilized in the development of the architecture.

Use any data source and data store

Utilizing APIs and communication protocols within custom development means that almost any device and data source can be integrated. Also, every open data store can be used and even mixed within a custom solution. This makes the underlying data available at any time for real time monitoring, historical analysis, and reporting using the tools of your choice.

Can host any user interface

Since the data is open, this also means any possible user interface can be developed, with your own company branding, which is necessary for OEMs and software resellers.

CONS

Upfront development may be required

With a custom solution, there’s no avoiding it. The software needs to be developed and tested before it can be rolled out into production.

No built-in user interface or apps

Because you’re starting with a blank slate, you can have any interface you would like, but that means none exist. All of the interfaces and tools need to be created.

Requires customization when requirements change

If your company grows, your requirements change, or you realize that your original assumptions were not entirely correct, the solution must be modified. Whenever a custom solution needs modification, that usually means more custom development, unless the modifications were planned upfront.

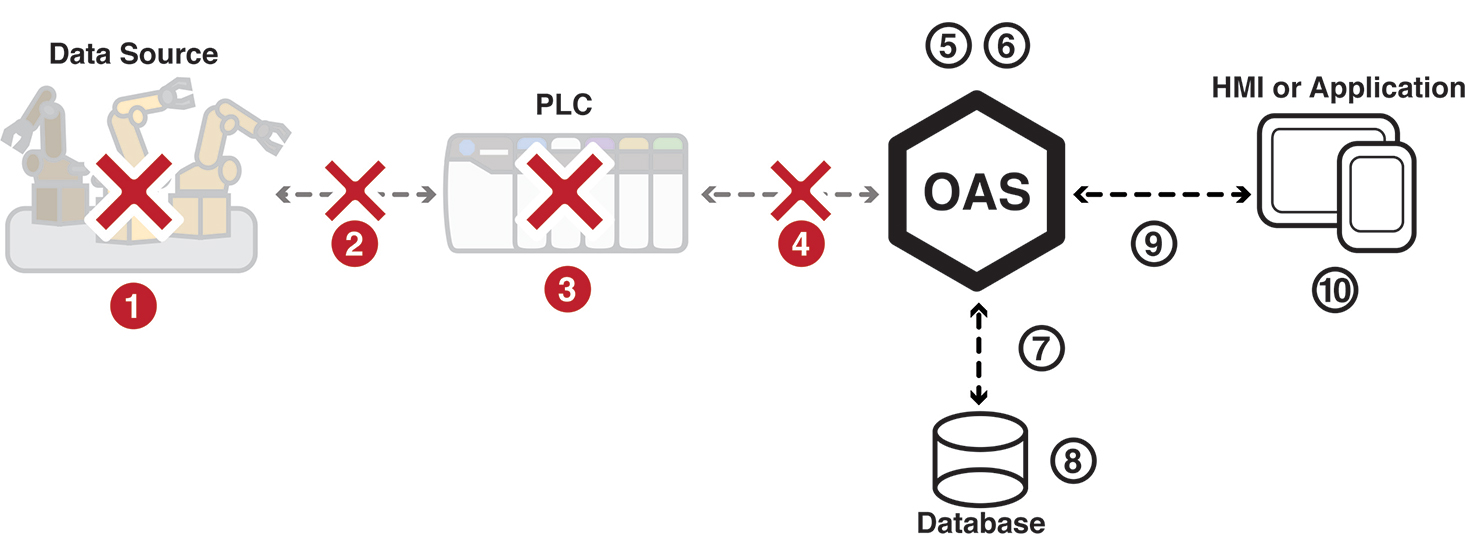

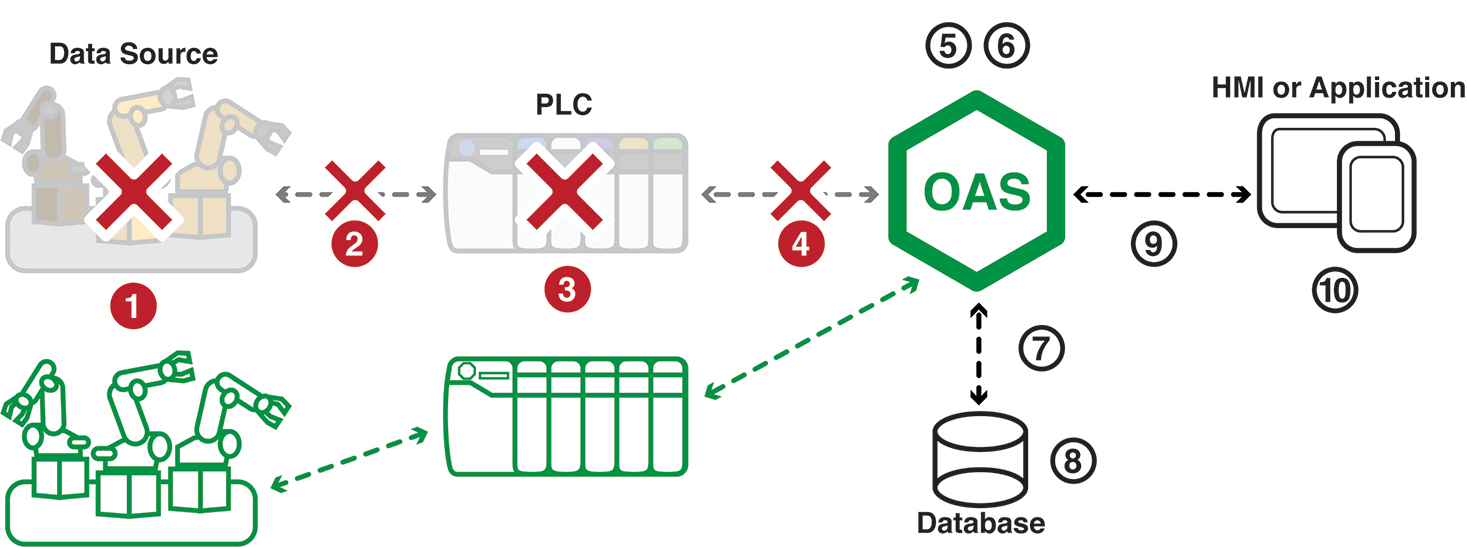

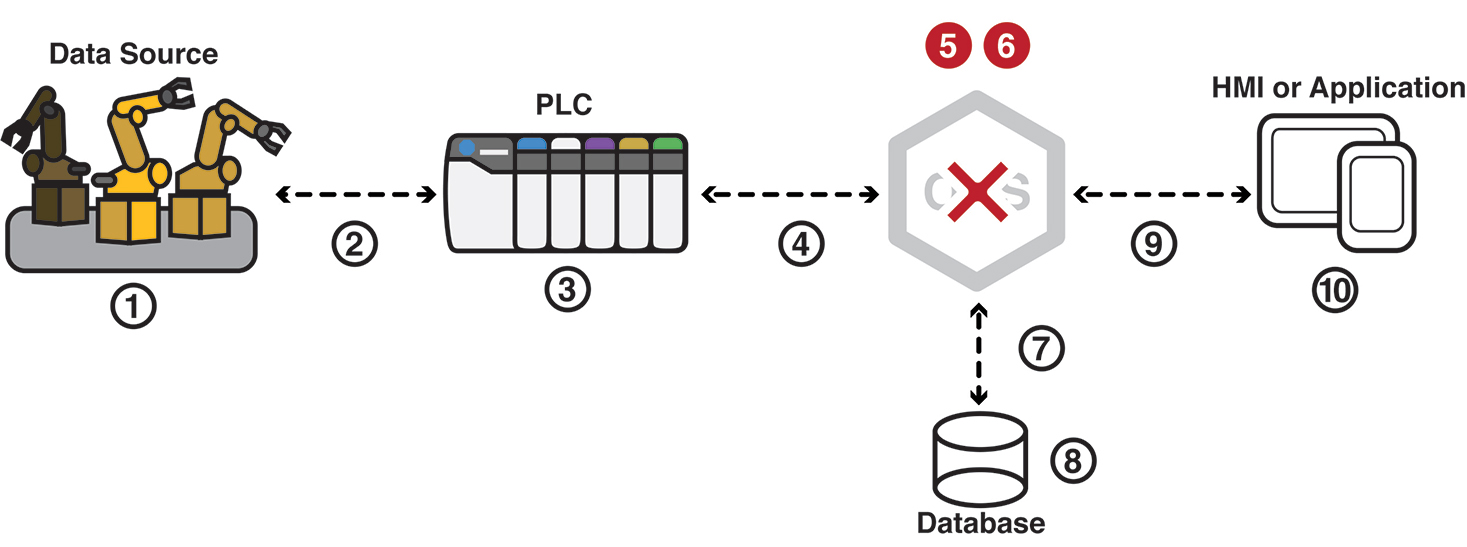

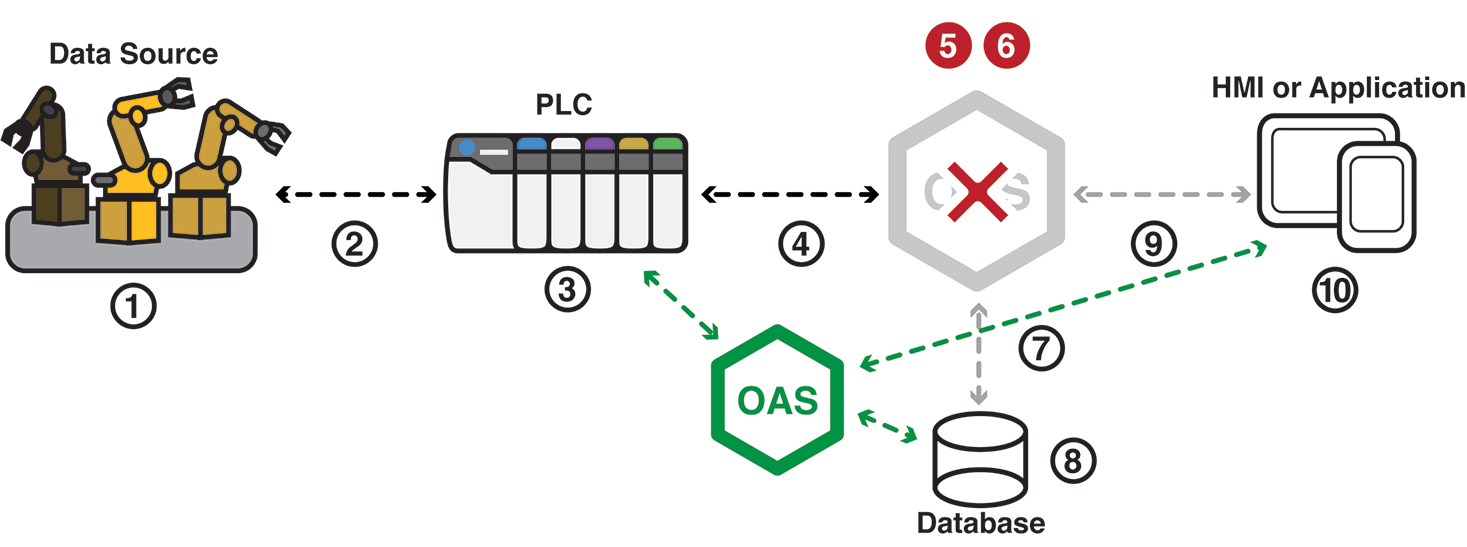

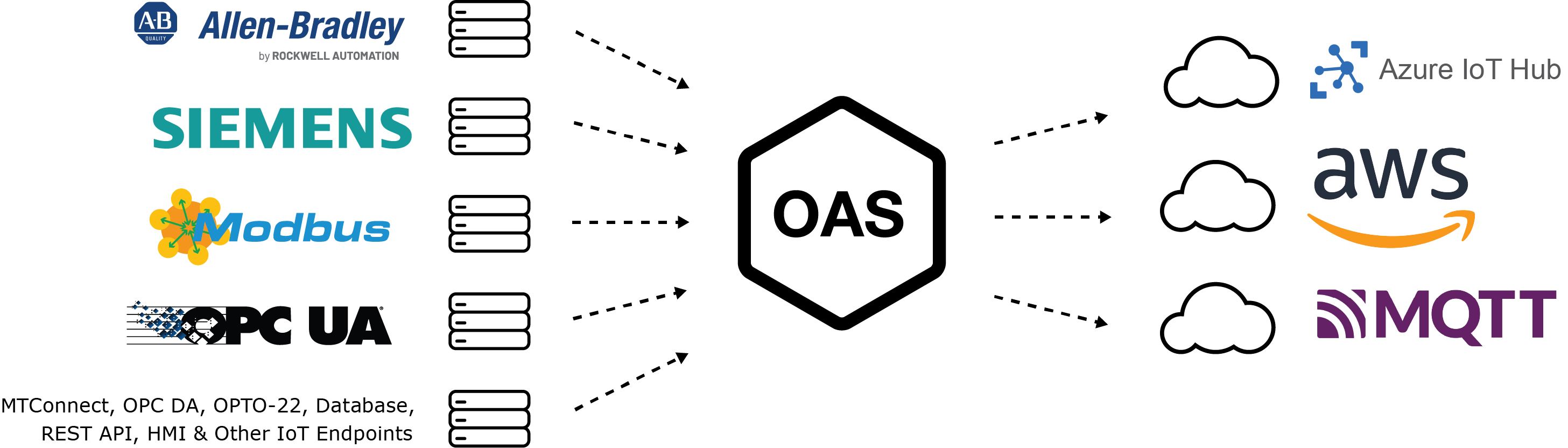

A Third Way: The Open Architecture

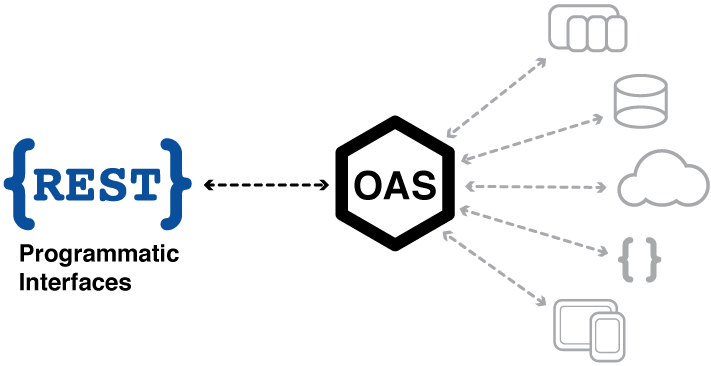

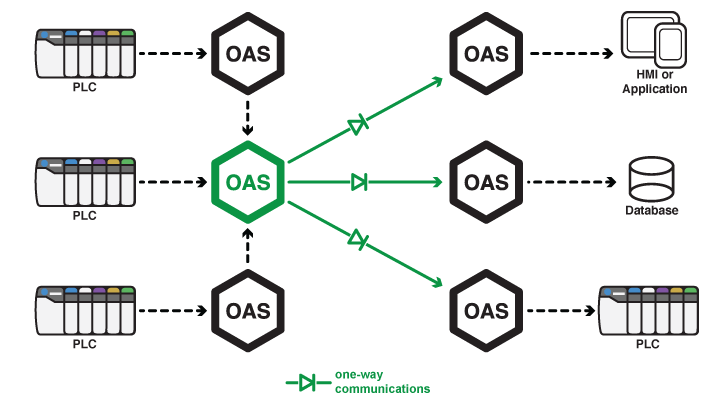

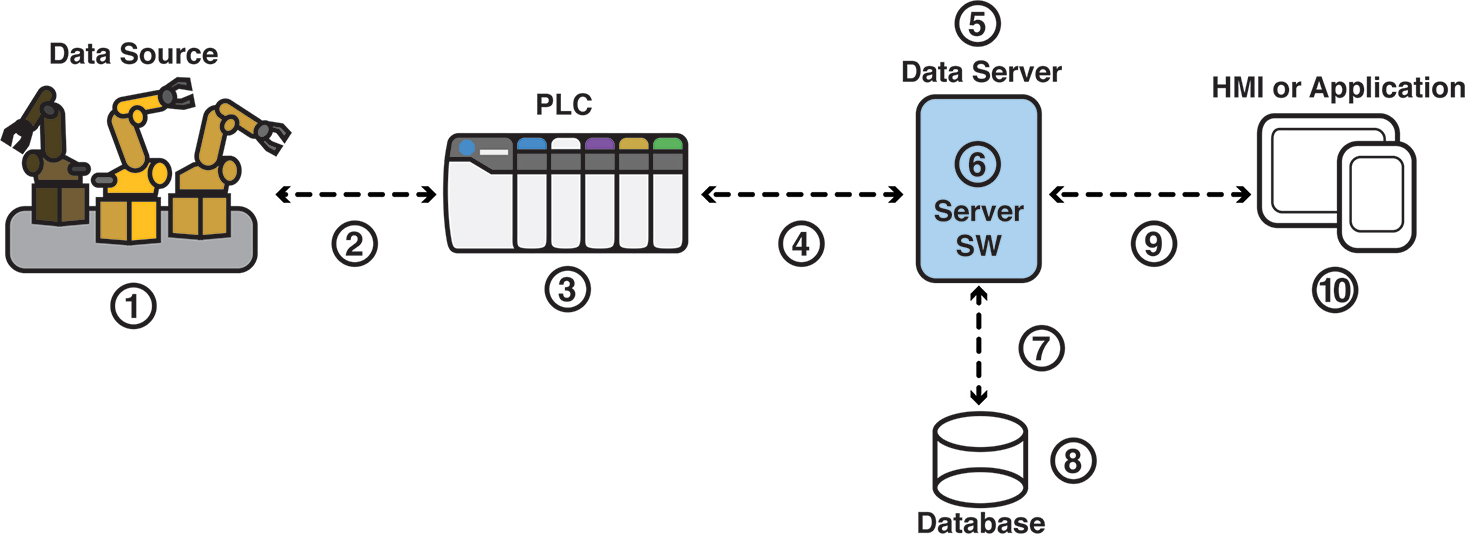

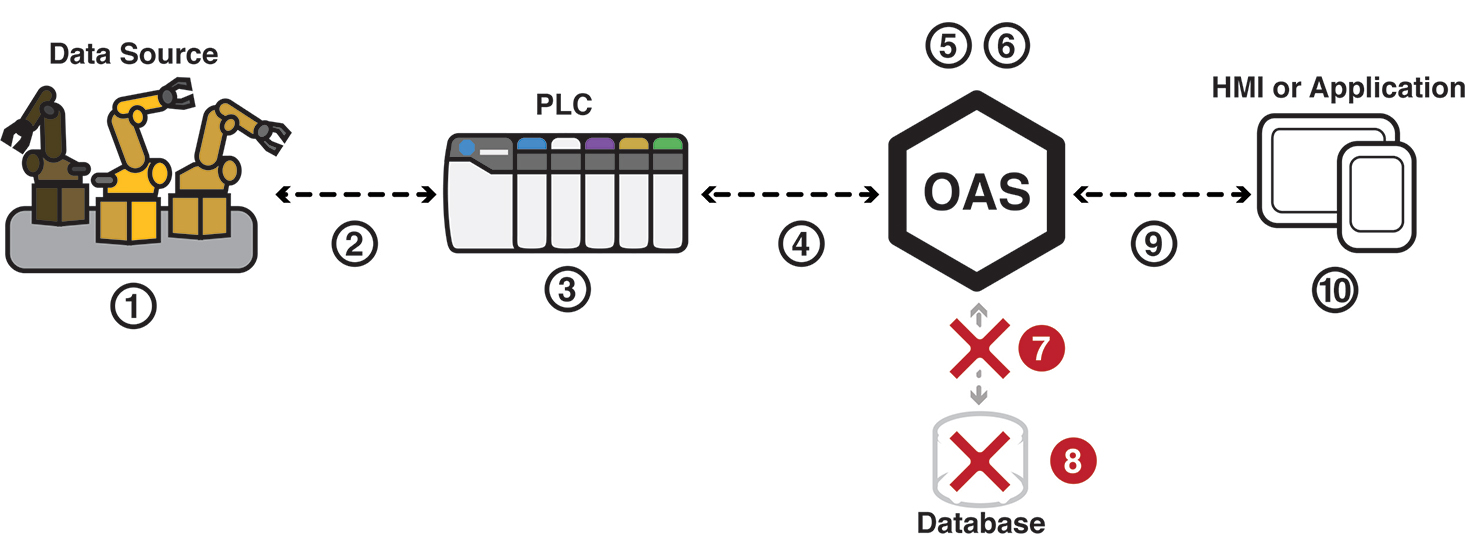

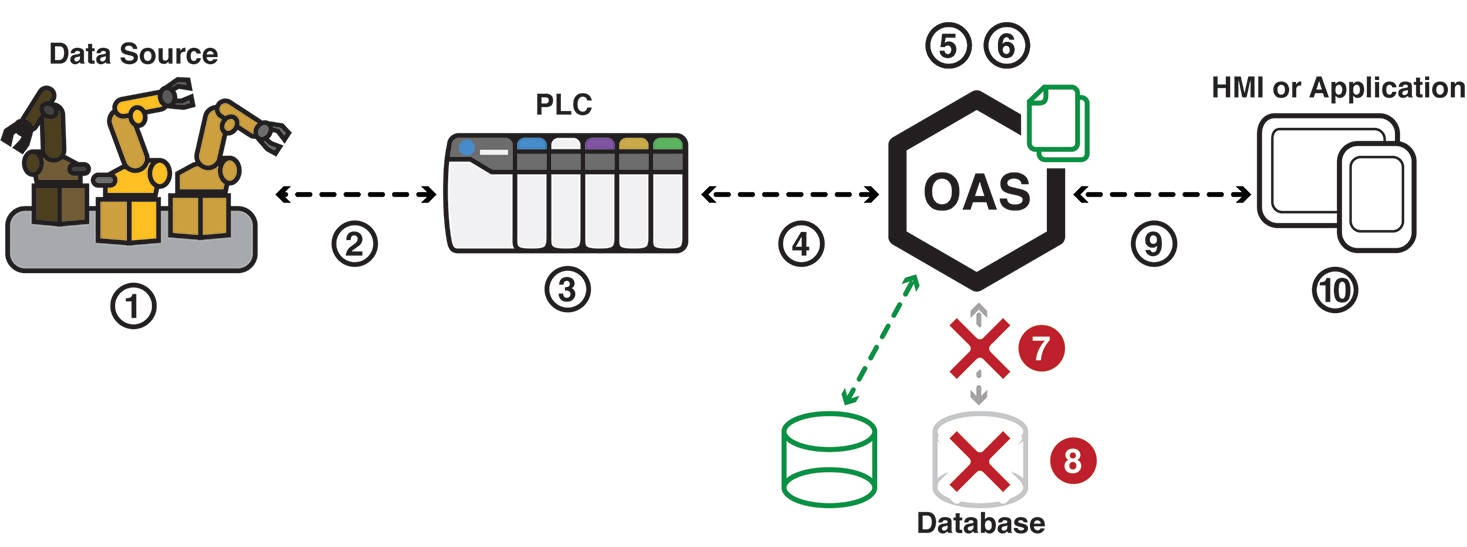

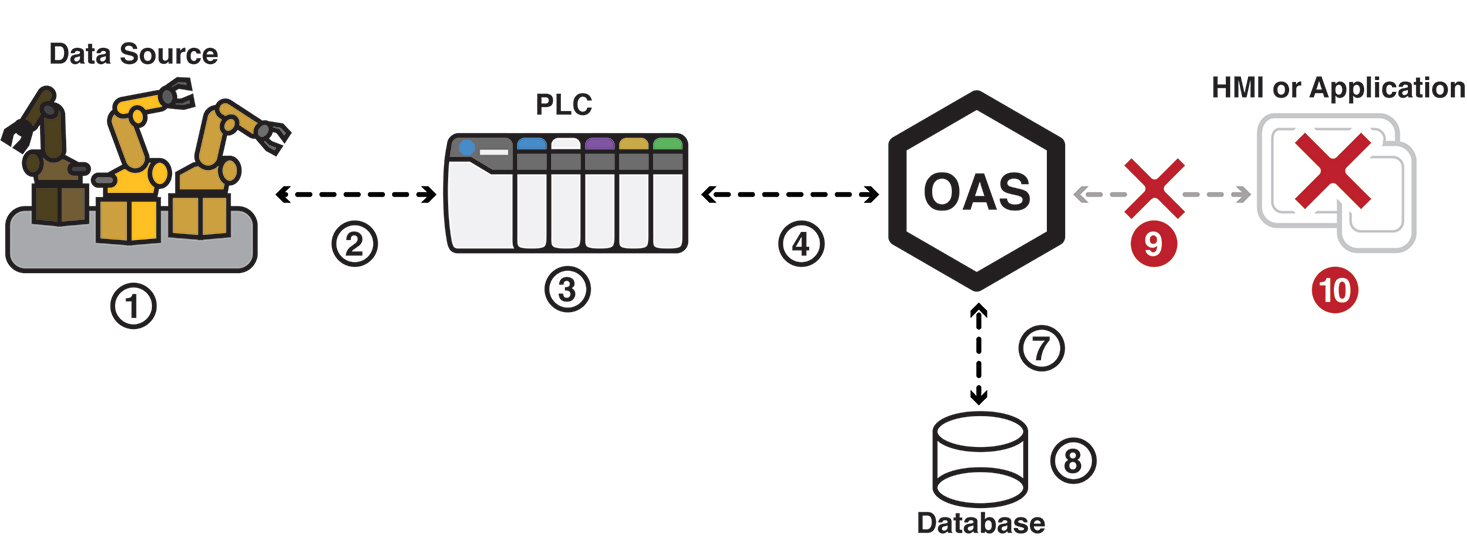

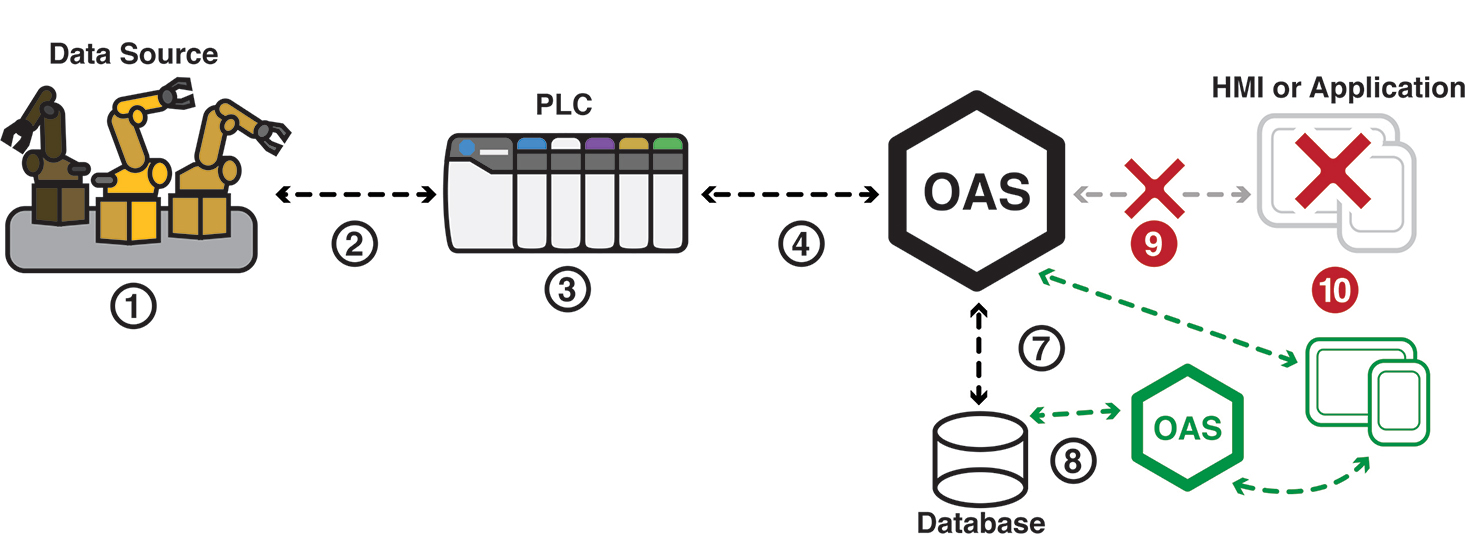

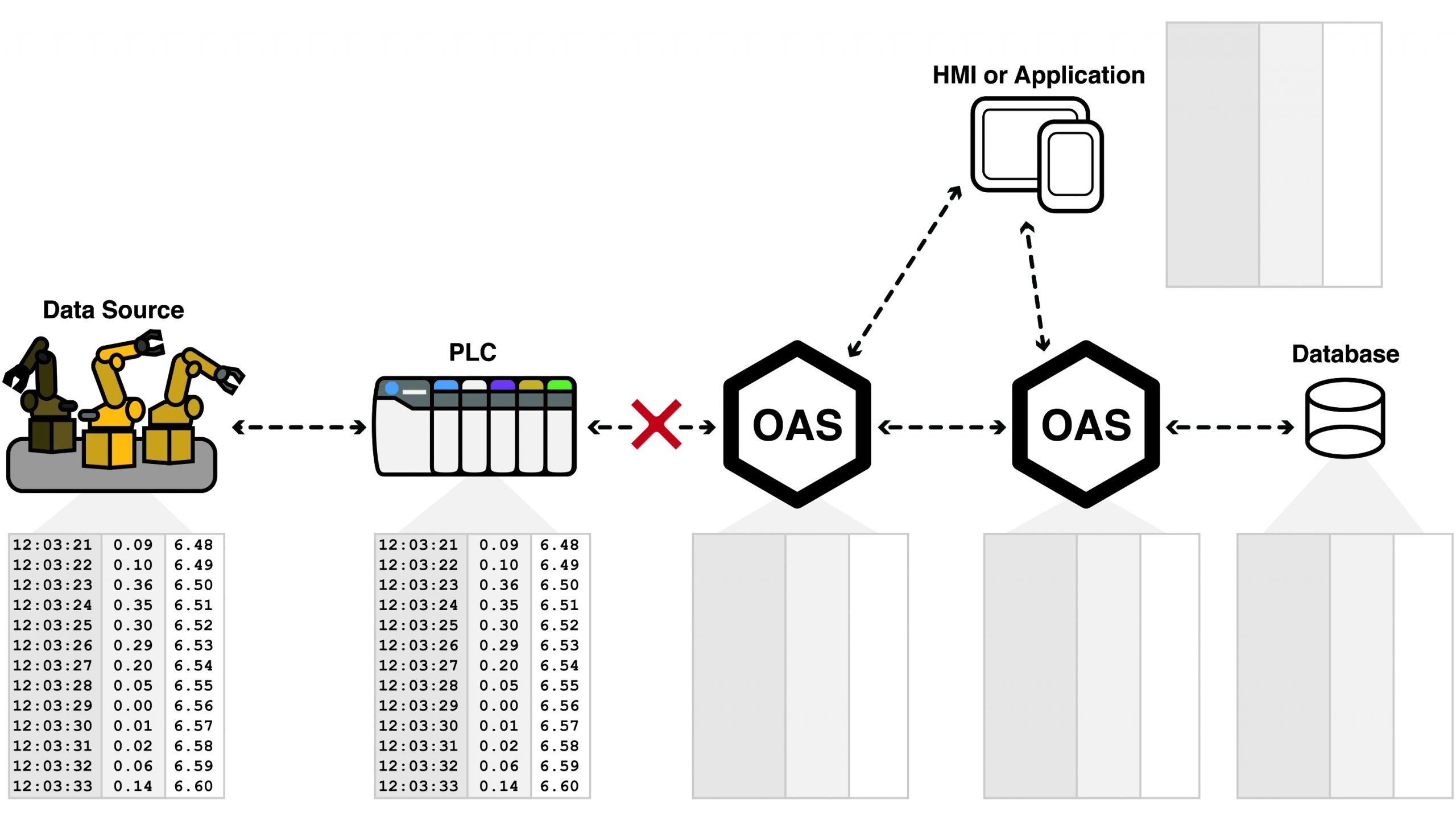

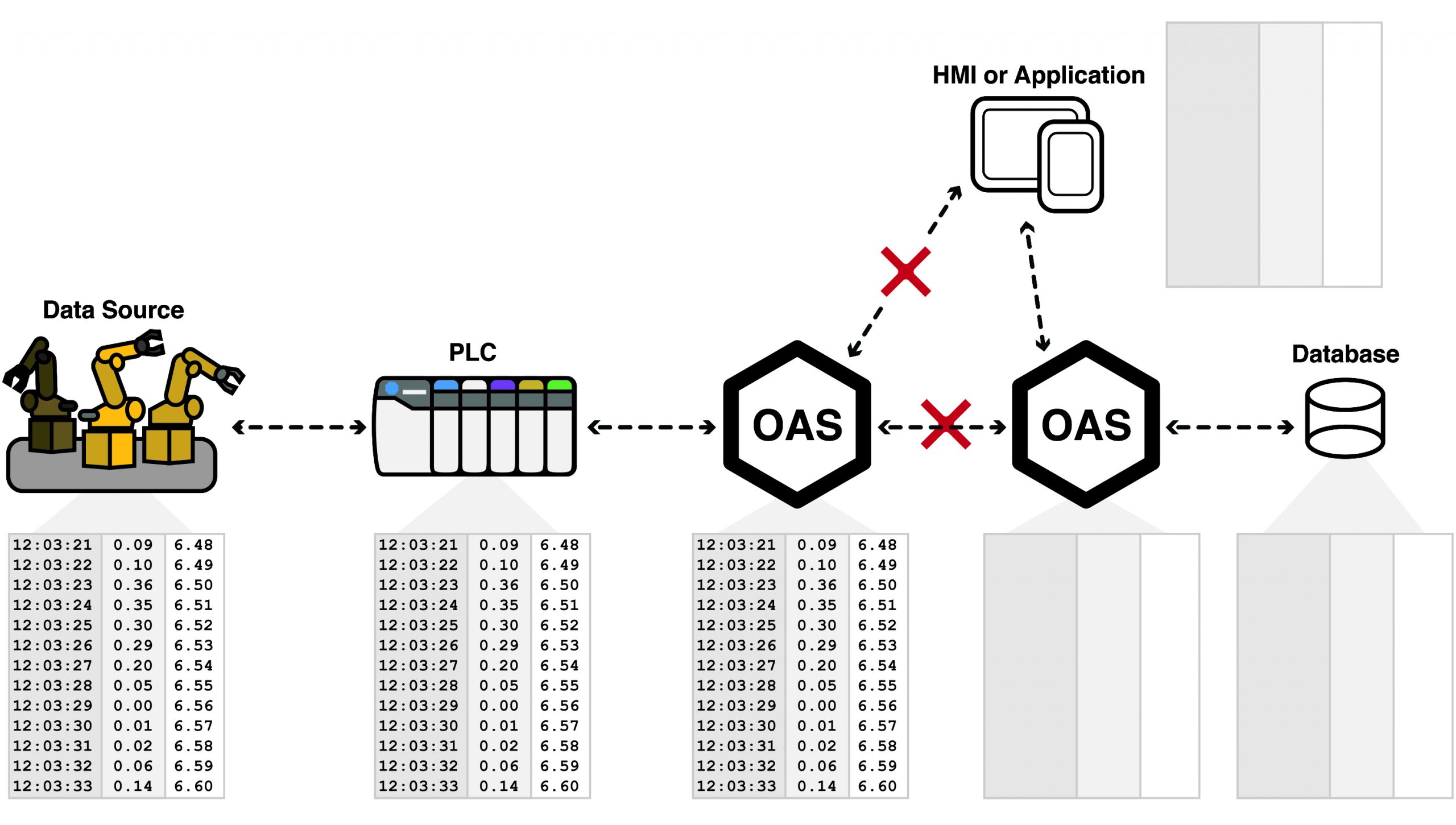

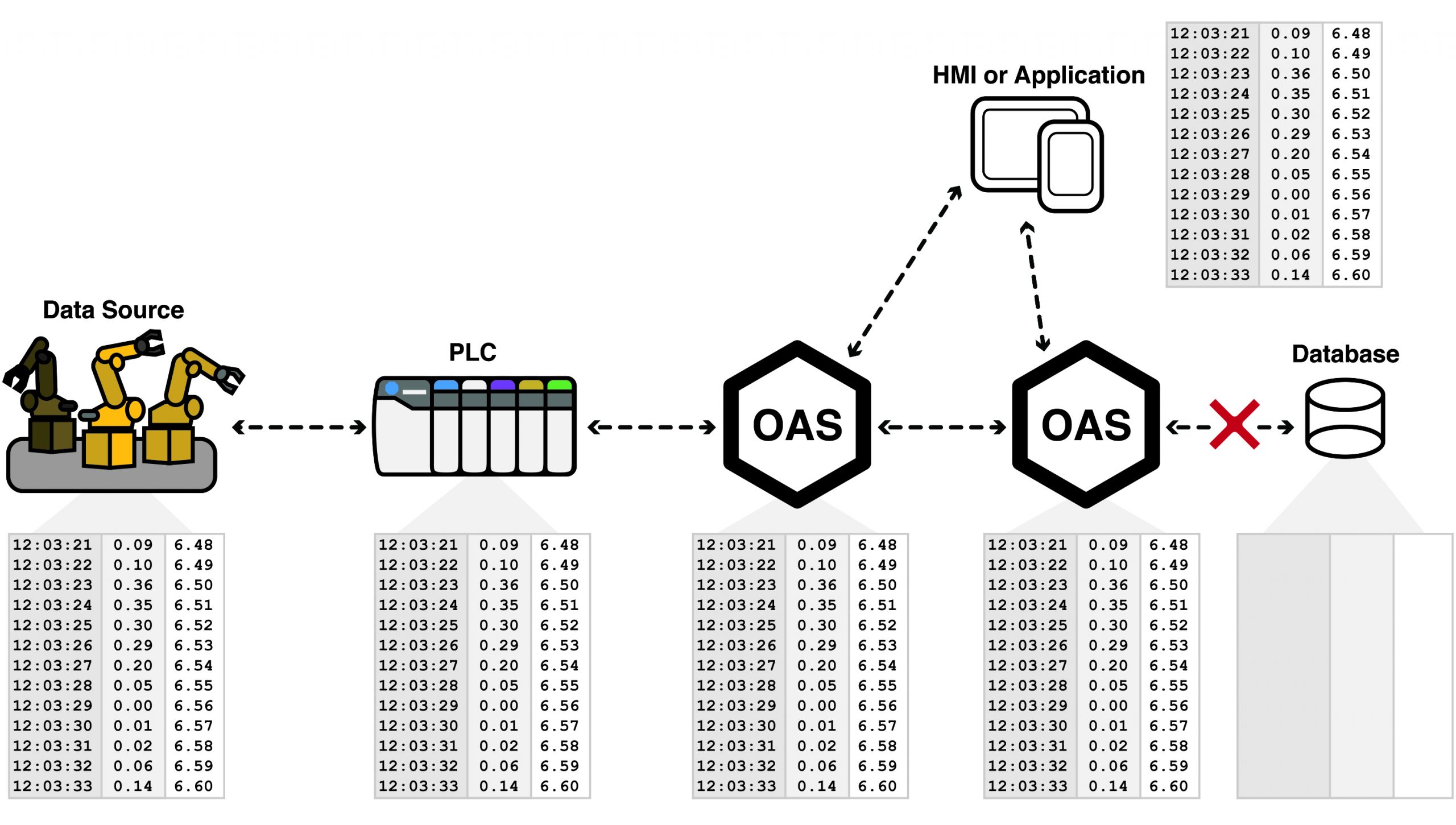

The OAS Platform is a robust alternative for building an Industrial Automation or IoT solution. The Platform mitigates many of the risks of pure custom development, while still offering all of the advantages of a custom solution. How is this possible? OAS provides a robust and scalable networked platform that can be connected to data sources and data stores, all through a set of configuration applications. At the same time, the OAS platform exposes a series of APIs and developer tools for the creation of custom applications and the complete automation of the entire system. The following are just a few of the features OAS offers:

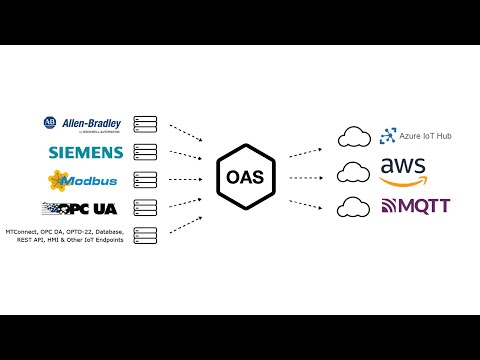

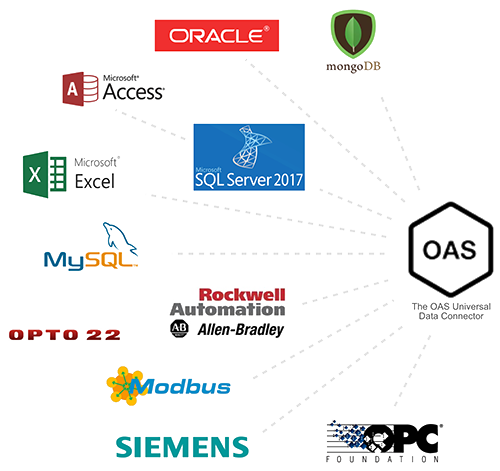

Universal Data Connector

Universal Data Connector

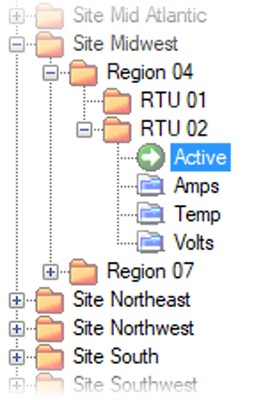

The UDC is a server platform that manages connectivity to devices, databases, file systems and more. It also includes native drivers for many standard PLCs and IoT components that can be connected and configured with no programming required. The UDC is able to be networked with other instances, distributing and aggregating data as needed at the fastest speeds possible.

Learn more about the Universal Data Connector

Flexible licensing for end users and OEMs alike

The OAS Platform offers flexible licensing. Whether you are an automation engineer, systems integrator, or software developer looking to use the platform as a component of your own products, OAS licensing can be adjusted to meet your needs. Licenses are based on the number and type of data sources being connected, not the number of clients connected.

Learn more about OAS Platform Pricing

Open data model

Your data is your data, so when the OAS platform moves data between source and destination, or when the data is stored in a database, it is always available in open formats. No proprietary tools are required, and no additional licenses are needed just to read or even move that data using other tools that you prefer.

Learn more about Device and Data Connectors

Learn more about the Data Historian

Automated configuration and deployment

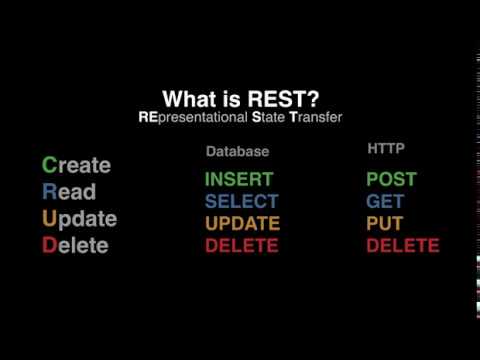

Every aspect of the server configuration can be automated using the various APIs that are exposed for .NET and REST clients. This means an OAS Platform can be programmatically configured and deployed, dramatically reducing costs for rolling out new installations when your organization or install base grows.

Learn more about OAS Developer Tools and APIs

Infinitely customizable using open development tools and APIs

Infinitely customizable using open development tools and APIs

Access to the OAS APIs and development components is available using open tools and with popular development environments and languages. Desktop applications can be written in any .NET language using Visual Studio. Many visual components are provided for both WinForms and WPF for real time data access and control, as well as for Trend and Alarm visualization. Web application developers can use the Web HMI, Web Trend, and Web Alarm products to deploy web-based visualizations on any web platform and any web browser, desktop or mobile. And using the .NET Core Components, native iOS and Android applications can be integrated into your solution.

The UDC also exposes several APIs for automation and customization. Software developers are free to build their own user interfaces using completely custom code, or they can use the many tools and controls provided for desktop, web, and mobile applications.

Learn more about OAS Developer Tools and APIs

Highly available and affordable resources

Because the OAS Platform can be configured and automated using open development tools and popular languages, it becomes much more affordable to apply resources to your next project. The pool of .NET and web developers available is one of the largest in the IT market, so ongoing maintenance risks are greatly reduced as well.

With OAS, OEMs and systems integrators can build custom solutions for automation and monitoring

With OAS, OEMs and systems integrators can build custom solutions for automation and monitoring