Industry 4.0 Data with Google IoT Core

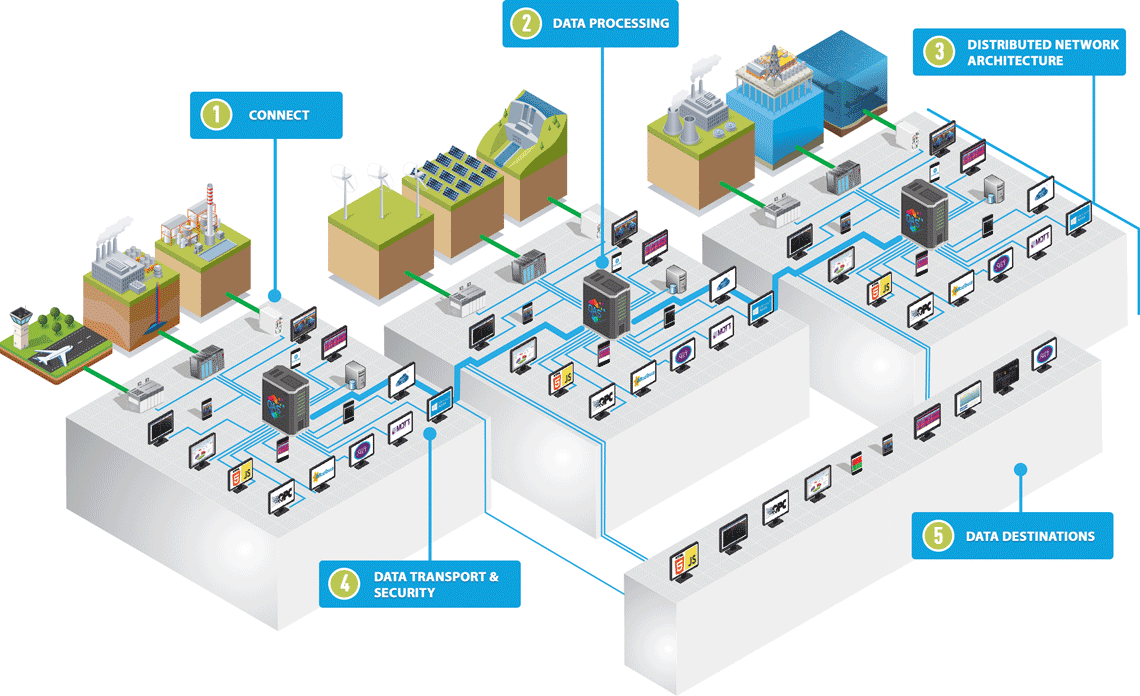

Google IoT Core is an Internet of Things (IoT) service from Google that allows businesses to manage their IoT infrastructure and data. Google IoT Core is comparable to Amazon’s IoT Gateway and Microsoft’s Azure IoT Hub.

The key elements of Google IoT Core include:

- Device management – an interface for managing and authenticating ‘things’ or devices

- Protocol bridge – provides the connection endpoints and management services needed to provide secure and reliable telemetry.

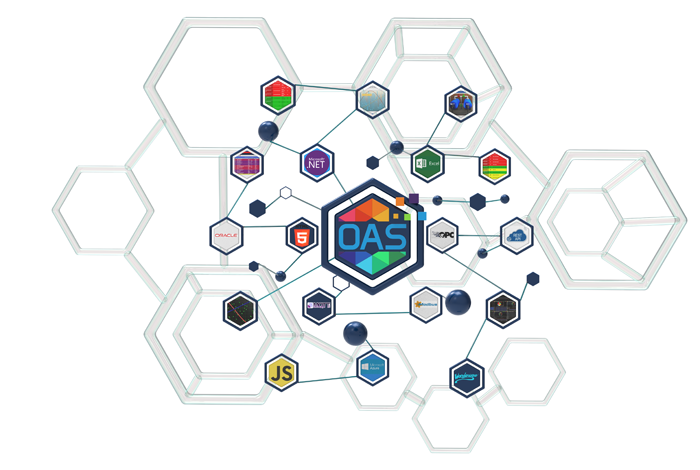

OAS Google IoT Core Interface

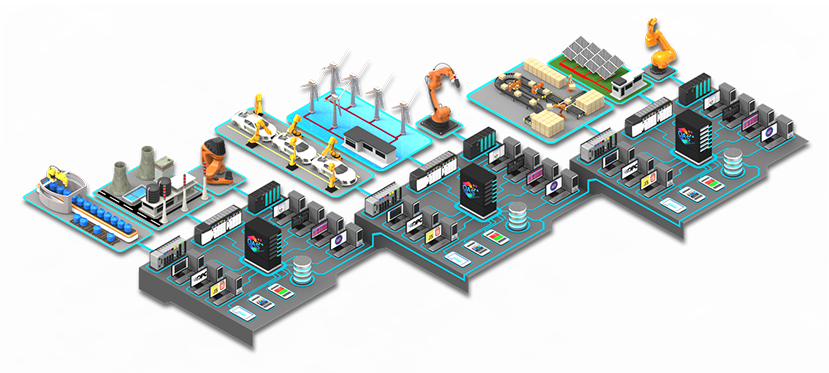

Always on the leading edge of Industrial IoT technology, OAS now includes support for Google IoT Core. Moving data from your local or remote data sources to (or from) Google IoT Core is straightforward with OAS. It doesn’t matter what the data source – with Open Automation Software you can move it to and from Google’s IoT Core framework.

Use the OAS Google IoT Core Interface to quickly, efficiently and securely move data to and from Google IoT Core and other systems. There’s no limit to the type and quantity of data you can move with OAS. Production data, energy monitoring, inventory, GPS data and more can all be automated with OAS. Harness your data to improve overall equipment effectiveness and improve supply chain efficiency.

Data quality is a high priority for IIoT Applications

For Industrial Internet of Things applications, data transfer has to be secure, accurate and fast. With OAS, data quality is verified via timestamp using MQTT. Take live local, remote or plant floor data and easily use it in big data analytics.

Write live data to devices within Google IoT Core using OAS’s built in MQTT protocol driver. This enables you to take full advantage of any or all of the other big data and IoT services provided by Google IoT Core. You can complement Google IoT Core with other OAS products; our Data Historian product is an easy and reliable way to move data to Google IoT Core.

MQTT – A Highly Efficient Protocol for Remote Devices

OAS Google IoT Core interface utilizes MQTT, a lightweight protocol that implements a client/broker architecture. Originally developed as a machine to machine (M2M) protocol by IBM, MQTT is now implemented in several open protocols.

Due to its client/server architecture and its small footprint MQTT is particularly well suited for small devices with limited power or network connectivity. A common application is to use this protocol on hundreds or thousands of remote devices that may have battery or solar power and be utilizing cellular or other limited or expensive communications.

Advantages of MQTT

- Small packet size = low overall bandwidth usage

- Great choice for limited connectivity – remote device connects to the broker when possible and publishes its updated state

- Able to both subscribe and publish to brokers making it easy to take remote device data and View, Historize, Alarm, Trend and Notify via Web, .NET, Email, Voice and SMS.

Share non machine to machine (M2M) data and share it with M2M devices and clients utilizing the analytics available on Google IoT platform.

OAS with Google IoT Core

Use Open Automation Software’s MQTT Connector to interface your industrial data with Google IoT Core.

Knowledge of common failure points helps guide data logging system design

Knowledge of common failure points helps guide data logging system design

How our systems protect your data on networks

How our systems protect your data on networks

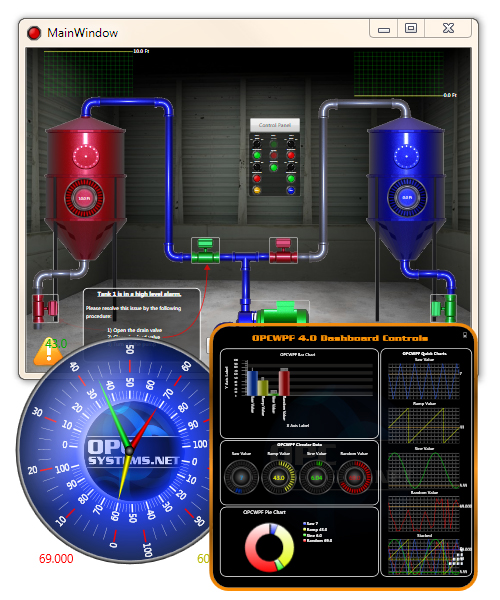

Like to know more about our WPF .NET product?

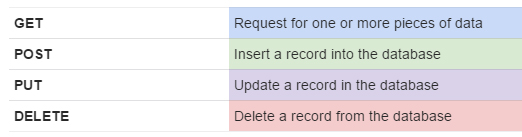

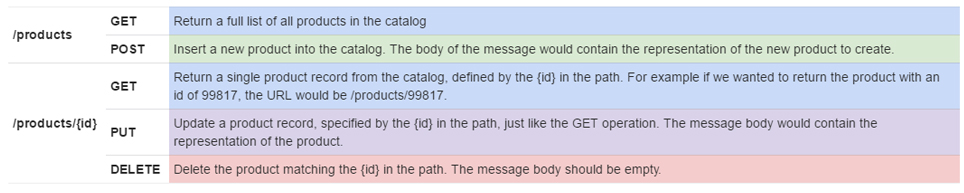

Like to know more about our WPF .NET product? What is REST?

What is REST?