What Is IIoT?

You might have heard of the Internet of Things, but you might not yet be familiar with the Industrial Internet of Things (IIoT). It’s all about how devices used in industrial processes communicate with one another and collect data. It’s an emerging idea in the industrial world, and it’s set to change things even more in the years ahead.

Read on to find out all about the Industrial Internet of Things (IIoT) and what it all means, both now and moving forward.

What is the Industrial Internet of Things (IIoT)?

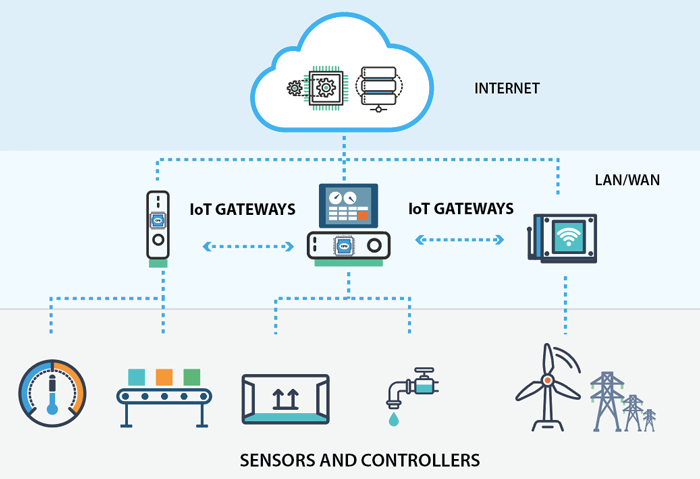

At its core, the Industrial Internet of Things refers to a wide range of industrial devices, such as machines, sensors, gadgets, networks, and motors, that are connected to each other. The devices contain sensors that are connected to networks that then gather data. They also communicate with one another as data is shared and transferred.

Thanks to recent tech advancements, the sensors used for these devices can be made smaller than ever. This means that now even very small industrial devices of various kinds can be connected, allowing for ever greater levels of monitoring, tracking, and data collection as they communicate with other devices.

The real strength of IIoT comes from how businesses can take that data and analyze it to better understand how their functions are operating and how their business processes are performing. The more data you have, the clearer your understanding of performance industrial processes and performance levels. And that’s one of the key reasons why the Industrial Internet of Things is so valuable.

What Can It Do for Businesses?

So, what does IIoT actually do for businesses? One of its biggest advantages is how it supports smarter decision-making. With a steady flow of real-time data, IIoT helps companies move past guesswork and base their choices on solid, actionable insights.

The level of detail provided in this data can be very high. Businesses and business owners can then understand their processes better than ever before, and in turn, this helps them to make their processes more efficient. As they make decisions, they can be led by the data rather than less tangible estimations that might not offer the same accuracy.

The Industrial Internet of Things also helps when it comes to managing supply chains better and coordinating directly with other businesses. When businesses work together better in a more carefully coordinated way, they can be made even more efficient. And that’s something that benefits both businesses.

Overall, these IIoT applications lead to real savings and a more flexible, efficient way of doing business.

How Does IIoT Differ from IoT?

Although there is some overlap between the two, it’s important to understand the difference. Both use sensors and network connections to help devices communicate and boost performance, but they serve very different purposes and operate on different scales.

IoT usually refers to everyday consumer tech, such as TVs, speakers, and smartwatches, and even home appliances like refrigerators and security systems. In this space, the focus is mostly on convenience and lifestyle improvements for individual users.

IIoT, on the other hand, is all about large-scale industrial environments. It’s more about planning, analysis, and business efficiency. As a result, there’s more analysis and data crunching that goes into IIoT.

Which Industries are Beginning to Adopt IIoT?

There are already a lot of companies using and benefiting from IIoT, and there are some industrial niches that are using it more than others. As we’ve mentioned, one of its biggest advantages is improved coordination, which makes it especially valuable for supply chain and logistics companies.

It’s also true that the world of manufacturing is starting to embrace IIoT. When manufacturing companies use the Industrial Internet of Things, it allows them to make projections about the most optimal and efficient timing of machinery servicing and things like that. This might not seem like much, but it can reduce the amount of downtime the company experiences.

But it doesn’t stop there. Businesses in retail, warehousing, and other sectors looking to better manage inventory and reduce waste can also benefit from IIoT. Even public sector organizations, like healthcare departments and transportation agencies, are using it to improve services and boost efficiency. IIoT’s flexibility makes it a powerful asset for just about any industry.

How Well Established is this Technology Right Now?

The Industrial Internet of Things isn’t some far-off idea; it’s already here and growing fast. Many companies are putting IIoT solutions to work, but there’s still a lot of room for growth as more businesses start to see the value of connected industrial strategies.

The Industrial Internet of Things is already being heavily invested in, with hundreds of billions of dollars being poured into it by businesses in a variety of industries and sectors every year. In recent years, those numbers have been growing, suggesting that IIoT is on an upward trajectory in terms of business spending.

There are many different things that businesses are spending this money on at the moment. A lot of the money is being spent on logistics and transportation to make supply chains better integrated with IIoT technology. That’ll make it possible for companies to benefit in the ways discussed above.

The Components Behind IIoT

The Industrial Internet of Things (IIoT) runs on the smooth integration of three main components:

- Sensor Technology: Thanks to major advancements, sensors are now smaller, more affordable, and easier to scale. They’re the eyes and ears of IIoT, collecting important data on everything from temperature to machine performance.

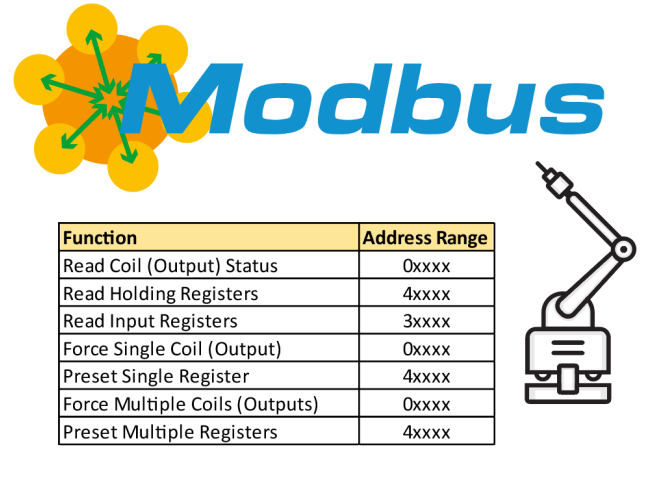

- Network Technology: A strong, reliable network is a must for keeping connected devices talking to each other. Whether it’s wired connections or wireless protocols, the right network setup keeps information flowing smoothly across an IIoT system.

- Analytics Technology: All that data pouring in needs serious processing power. Advanced analytics tools help sort through the noise, turning raw data into clear, actionable insights that businesses can actually use to make smarter decisions and streamline operations.

The exact mix of devices and technologies used in an IIoT setup depends on the industry, specific goals, and business needs. This flexibility of industrial IIoT is what makes it so valuable across so many different sectors.

Security Matters

Security is one of the things that you need to think about if you’re going to start using the Industrial Internet of Things. The devices usually used to create an IIoT setup are not ordinarily intended to be connected with other devices and networks. They certainly can be, but you also have to accept that this brings with it an increased threat and risk level.

To ensure you don’t end up being hit by some sort of cyber hack or attack, you need to put in place the proper security measures. Basic things like strong password protection are key, but there needs to be a broader security strategy in place that can back you and your systems up.

Research has found that one of the main reasons making businesses hesitant to implement IIoT systems is the security worries that they have. That doesn’t need to be something that prevents businesses who would benefit from the Industrial Internet of Things from using it; it should just mean that extra security planning takes place.

Better Speed and Reliability for IIoT with OAS

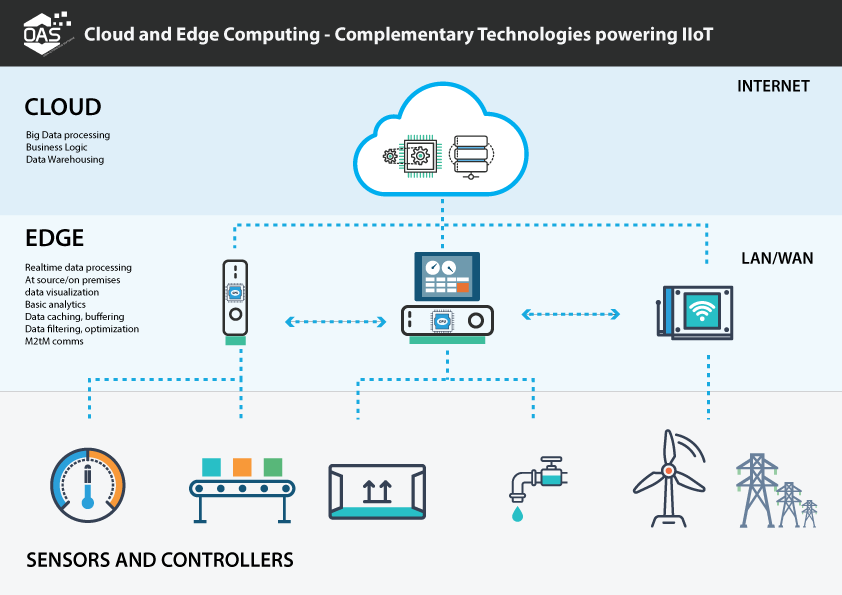

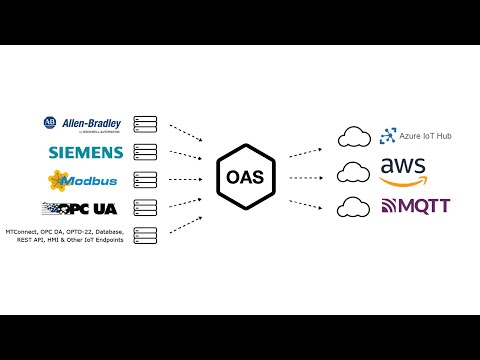

The Industrial Internet of Things is a new revolution, but it requires an enormous amount of data to be transferred and stored, and only edge solutions can provide the performance, reliability, and speed required to do this efficiently.

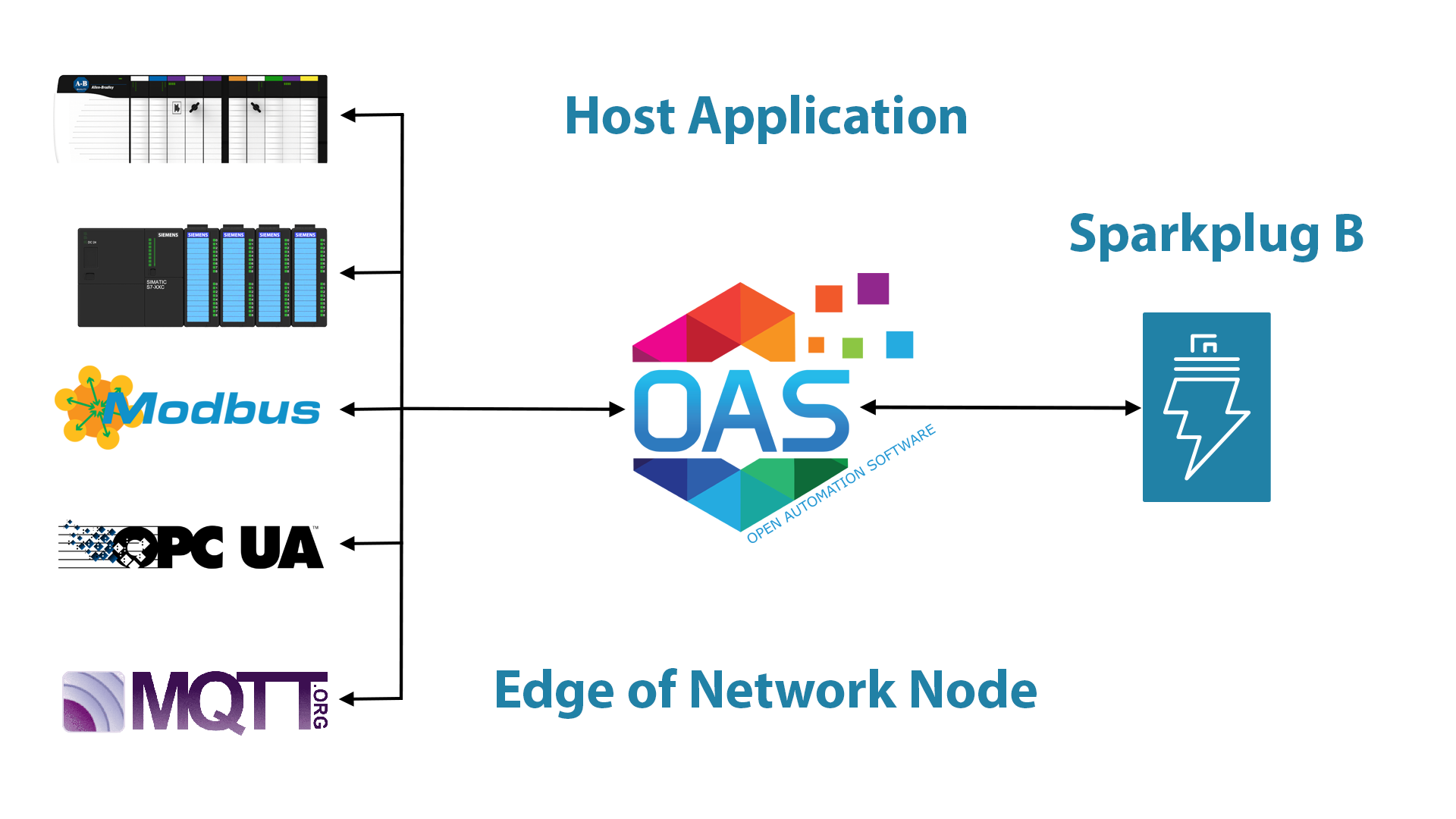

Open Automation Software (OAS) has been so valuable in this type of efficient computing for accessing, logging, and displaying data closer to the source from which it’s generated – as well as for its speed, accuracy, and design philosophy as an open network that is easy to implement and cost-effective – that it is utilized for many high-volume systems, such as in Intel’s manufacturing plants and by the U.S. Navy on its nuclear submarines and aircraft carriers.

OAS and Its Many Applications In IIOT

With the OAS platform, almost every industry can find the best-in-class IIoT solutions for high-speed and reliable data logging and transfer, device management and control, and security across network communications.

Building Automation Systems (BAS) have been developed through the OAS Platform by customers for years, being used in commercial property for lighting, HVAC, safety, and security, and in ways that control building operations in more efficient, cost-productive solutions.

With the OAS Data Historian, time series data and event-based data can be collected over an entire building automation data spectrum to observe and act in predictive maintenance, detect downtime, and asset management for a level of advanced control more proficient than ever before in productivity and cost efficiency.

Open Automation Software offers complete operational visibility and connectivity between assets for businesses in the manufacturing industry. With real-time insights and accurate data, AI and human abilities are more efficiently merged, operational costs can be reduced, and customer/product interaction can be enhanced for enhanced marketing and product development.

IIoT integrated with the OAS platform offers endless possibilities. But its applications extend far beyond smart buildings and manufacturing. This system is being effectively implemented in a wide range of industries, such as in the:

- Marine industry

- Mining industry

- Packaging industry

- Shipping industry

- Water industry

- Chemical industry

- Recycling and waste management industry

- Telecommunications industry

- Construction industry

- Robotics industry

- Transportation industry

- And more

Getting Started with IIoT

If you want to get started with the Industrial Internet of Things, the first thing you’ll need to do is identify your goals and what it is you want to achieve. Every business and every project is unique, so only you can identify the goals and needs that have to be addressed as you implement your first Industrial Internet of Things system.

Some projects will be all about monitoring for efficiency or operational performance, others might be integrated with automation, and others will be about predicting future maintenance needs and minimizing downtime as much as possible. You need to identify the specific technologies that you want to make a part of your Industrial Internet of Things system.

From there, you should learn about how to store and analyze data if that’s something that you plan on being a part of your IIoT setup. It’s something that most businesses will want to do in some form or another. It’s also important to remember that it’s a process and that you can make tweaks and changes in the future.

Ready to put the power of the IoT to work for your business? Open Automation Software offers the secure, reliable, high-performance platform you need to build successful IIoT applications. Explore our platform today and start moving toward a smarter, more efficient future.

What is Edge Computing?

What is Edge Computing?