Access Siemens Device Data Anywhere

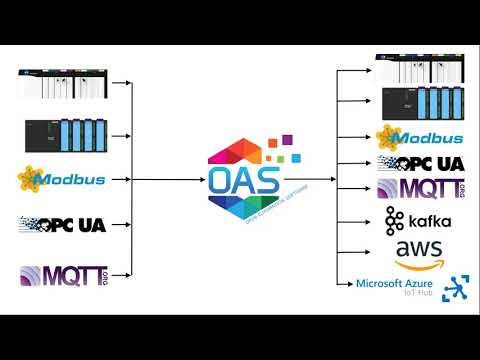

The OAS Siemens Data Connector is a powerful solution for seamless data transfer to and from Siemens S7 controllers using Siemens PLC software. With complete bidirectional communication across all OAS product features, you can harness your data where it matters most.

a server-based, highly-scalable, network platform that enables the transport and transformation of your data

Data HistorianAchieve fault-tolerant logging, zero data loss, and multi-destination storage with our high-performance Store and Forward technology.

Visualization ToolsBuild Visualizations, User Interfaces, and server configuration interfaces for .NET, web technologies, native iOS and Android mobile apps

Device & Data ConnectorsThe OAS Platform provides rapid communications and connectivity to a wide variety of PLCs, devices, and databases.

IoT ConnectorsConnect to cloud-base IoT gateways such as AWS, Azure IoT Hub, Azure Event Hubs, Kafka, and more.

Alarm Logging & NotificationCapture events on each data point, log to open formats for historical analysis and archiving, and trigger real time notifications

SDKs & APIsExplore a wide variety of Developer Tools and APIs to allow you to create applications and system integrations to execute in any environment.

Networking FeaturesOpen Automation Software implements edge computing with a Distributed Network Architecture.

Download a fully functional trial of Open Automation SoftwareKey Features & Benefits

Full Range of Controller Types Supported

OAS supports a wide range of Siemens controllers through native Siemens controller software integration. This includes:

S7-200

S7-1200

S7-300

S7-1500

S7-400

The result is optimized performance and easy setup using familiar Siemens PLC software and Siemens SCADA software tools.

Reliability

Adjustable timeouts and automatic recovery processes help maintain reliable connections. In the event of a network failure, the system can automatically switch to a backup controller. These features are critical for maintaining uptime in software SCADA Siemens environments.

Direct I/O, Memory, and Data Block Access

You can directly access Inputs, Outputs, Memory Bits, Variable Memory, Counters, Timers, and Data Blocks using absolute addressing. This is especially useful for advanced configurations involving software for Siemens PLC applications.

For the full list, see Siemens Address Syntax

High Speed Performance

The platform supports high-speed parallel processing with updates as fast as 15 milliseconds. With the ability to manage up to 1,000,000 tags per server, OAS delivers the throughput needed for high-performance Siemens HMI software systems.

Data Accuracy

OAS processes data in a first-in, first-out (FIFO) manner. This ensures no data is skipped, which is essential when using a Siemens IoT gateway or building detailed historical records with SCADA tools.

Common Use Cases

Logging Data to Databases or CSV Files

Use the OAS Data Historian to log data from Siemens S7 controllers into SQL Server, Oracle, MySQL, PostgreSQL, SQLite, and others. This logging can be triggered by changes in the data, specific events, or continuously. The system also supports logging high-speed buffered data from a controller. Learn more.

Data Transfer

The Data Route feature helps transfer data between Siemens S7 controllers and various Industry 4.0 data sources. It supports continuous or event-based transfers. The Siemens connector software also works with Basic and Live Data Cloud Networking tools to ensure smooth communication across your local area network (LAN), wide area network (WAN), or the Internet. Learn more.

User Interface

Create Human Machine Interfaces (HMIs) for Siemens controller data using the cross-platform UIEngine without any coding required. It includes drag-and-drop tools and supports Web Trend and Web Alarm products.

OAS works with Siemens HMI software and offers support for: WinForm HMI, WPF HMI, and Web HMI, as well as programmatic access through the .NET Data Connector and OAS REST API. These options allow you to seamlessly integrate Siemens data with your existing legacy applications. Learn more about the UIEngine

Learn how thousands of customers are using the OAS Product Platform around the globe to achieve truly open industrial automation

24/7/365

Support

Technical support available by phone, chat, and email

30+ Years

Experience

Product efficacy, market testing, and reliability

Used in 10K+

Data Servers

OAS is used in thousands of businesses worldwide

OAS Platform Features

Cross-Platform Support

OAS works across Windows, Linux, Docker Containers, and can even run on low-footprint devices such as a Raspberry PI 4.

Networking

OAS is an edge solution that offers flexible networking options for standalone installations, multi-tenant data aggregation, and even secure unidirectional data transport.

Programmatic Setup

Automate setup using our .NET SDK or REST API. Import and export CSV files to quickly integrate with Excel or other third-party tools. These options simplify deployment and help streamline workflows.

Calculations, Time On, Counts, and Totals

Merge data from various controllers and additional data sources while performing real-time computations and logic processing, all without the need for coding. Monitor the duration of activities for specific points and the frequency of their transitions over a defined period. Aggregate analog values both daily and over the entire timeline.

See How We Compare

The initial cost of OAS is far less than our competitors – but the savings don’t stop there. We work with OEMS and System Integrators to provide perpetual licenses with quantity discounts with flexible tag pricing and unlimited client connections.

No Question Left Unanswered

We make getting started with OAS easy - Browse our extensive Knowledge Base of articles on Getting Started as well as How To content that takes you step-by-step through building a solution, and finally learn more about specific features and configurations.

Getting Started - Download, Setup & Support

Step-by-step introduction to using the Open Automation Software platform

An overview of the fundamental configuration steps and a description of commonly used parameters.

Getting Started - Siemens S7 Driver

Follow these essential steps to effectively use the Siemens S7 driver, including the setup of the driver and the configuration of tags.

How to define addresses to access inputs, outputs, memory, and data blocks for various data types.