Many enterprises that use industrial automation and control systems in their day-to-day operations face the challenge of running production systems that haven’t changed for years or even decades.

You might know the story:

There’s barely anyone left in the business who understands these systems and they’ve been sitting on the security audit to-do list for years. The servers are about to fall over, but they are critical to business operations. There isn’t anyone brave enough to get the systems out of the “too hard” basket. Issues are difficult to fix, and those that do get implemented are just patches on top of patches, and innovation is non-existent as no one would dream of touching anything that might cause a failure.

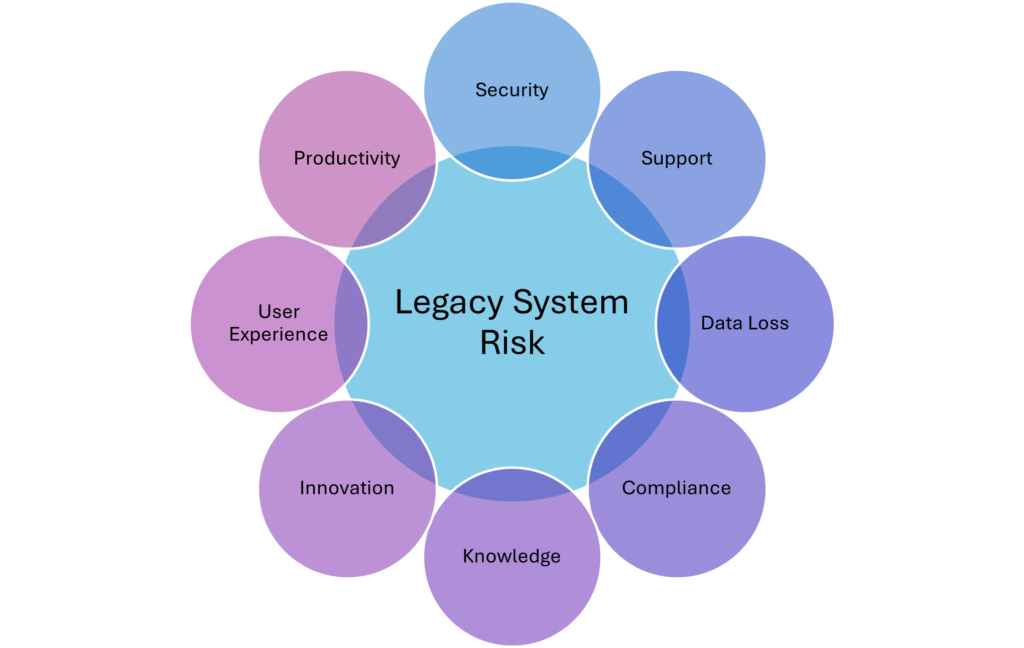

As these systems continue to linger on basic life support, your business is not only facing the immediate risk of down-time but there is a raft of other risks that are costing your business. Some of these risks are easy to see, yet others are more difficult to quantify.

So What Can You Do About It?

In many cases the best course of action is to simply start again as there are better ways to do things using the tools that are available in today’s technology landscape. However, it should be done in a way that allows as much configuration and operational data as possible to be migrated and re-used.

This is not an easy journey and requires an approach that starts with an understanding of the business, the processes, the data and ultimately a set of requirements that will produce the desired outcome.

In the real world it is unfortunately not as easy to engage an entire team of business analysis and architects and start again. First of all, existing processes don’t change easily. Secondly, you are not starting form a clean slate. There is already data that must be re-used and cannot be easily restructured.

This means you have to find a way to move data from an existing legacy system and bring it into a new system, bit by bit, and often with some transformations on the way.

Import Legacy Data Using OAS Configuration Import Features

The Open Automation Systems (OAS)🔗 platform and its configuration import features can help you with this challenge. The configuration import features are designed to help you move data from the clutches of legacy systems and into a modern operational environment. OAS is an enterprise automation system with a key focus on getting the best value out of your data. This is enabled through the ability to transport data from and to virtually any device or platform and being able to transform, control and visualize that data.

One of the key aspects of OAS that makes it great for migrating from a legacy system is the wide range of configuration options that are available. In this article we will examine a set of features that OAS provides to give you both functionality and flexibility.

- Mass Data Import using OAS CSV Import

- OAS Configuration .NET API

- OAS Configuration REST API

- Combine OAS CSV Import via .NET or REST API

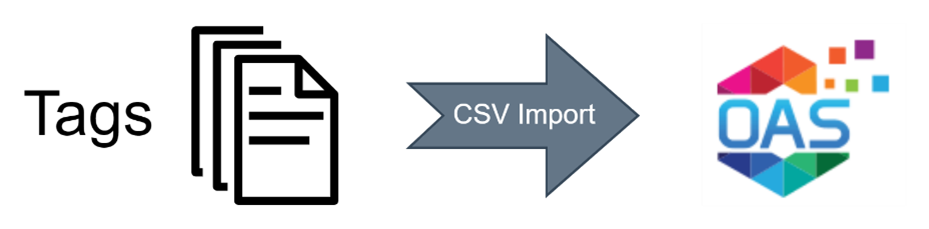

Mass Data Import using OAS CSV Import

The easy solution is to import your tag data into OAS using plain-text CSV files.

Export your data from your legacy systems or databases and use a well-known tool like Excel to build your OAS configuration as CSV files. This can then be imported with a few clicks in the OAS Configuration tool.

This is one of the fastest ways to simultaneously import a large number of tags (variables) into OAS. The best thing is you don’t need developers to write custom code!

👉 Get started with CSV import: https://openautomationsoftware.com/knowledge-base/tag-csv-export-and-import/ 🔗

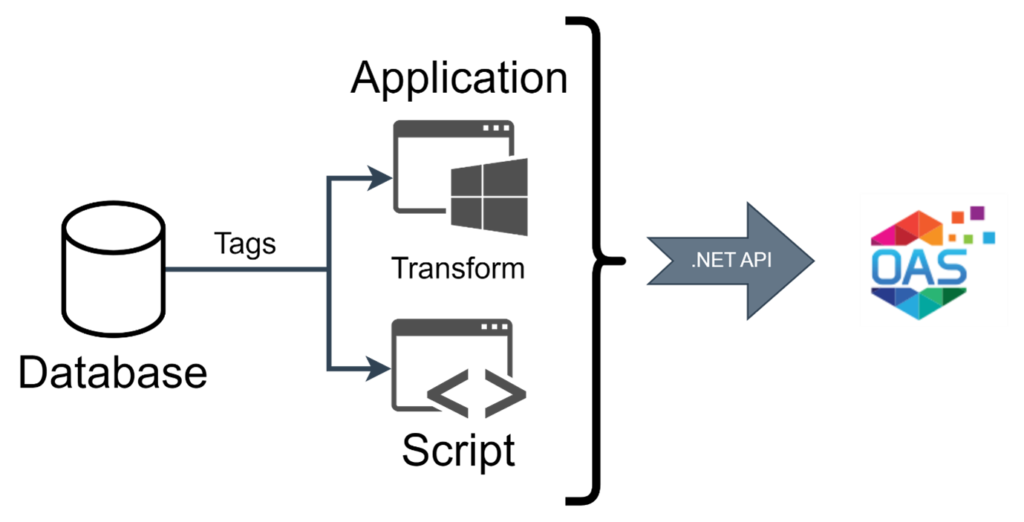

OAS Configuration .NET API

For more complex requirements, you can use the OAS Configuration .NET API to programmatically import your configuration data into OAS.

Your developers can use the .NET development framework to build applications or scripts that read configuration data from existing databases, transform it and pass it into the OAS Configuration API.

This method can be used to add Tags, Drivers, Databases and other OAS features. This is a powerful way to automate the import of data from legacy systems into OAS.

Even for simple use cases, the benefit of using the OAS Configuration API rather than the CSV import is to eliminate human error, allow for repeatable results and automate data transfer from legacy systems during testing phases.

👉 Get started with the OAS .NET Configuration API: https://openautomationsoftware.com/sdk/articles/oasconfig_gettingstarted.html🔗

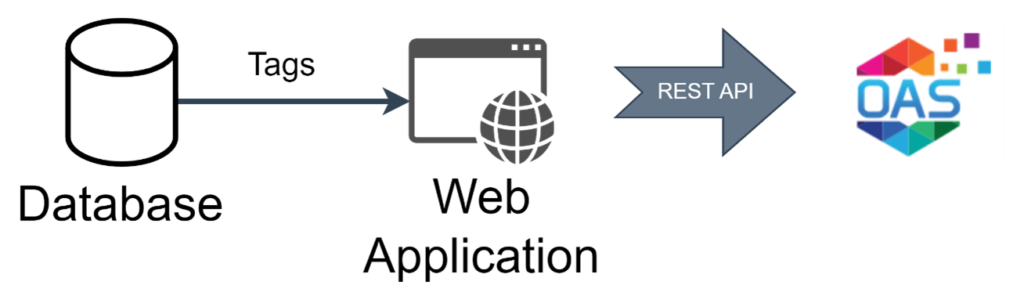

OAS Configuration REST API

For a more platform agnostic and web-ready approach you can use the OAS Configuration REST API.

This option provides the same functionality as the .NET method above, but your developers can get started using standard web technologies and don’t need to be familiar with the .NET development frameworks.

If your development environment and language support the HTTP protocol, you can use the OAS Configuration REST API. The best part is it is included with every OAS instance!

👉 Get started with the OAS REST API: https://restapi.openautomationsoftware.com/🔗

Combine OAS CSV Import with .NET or REST API

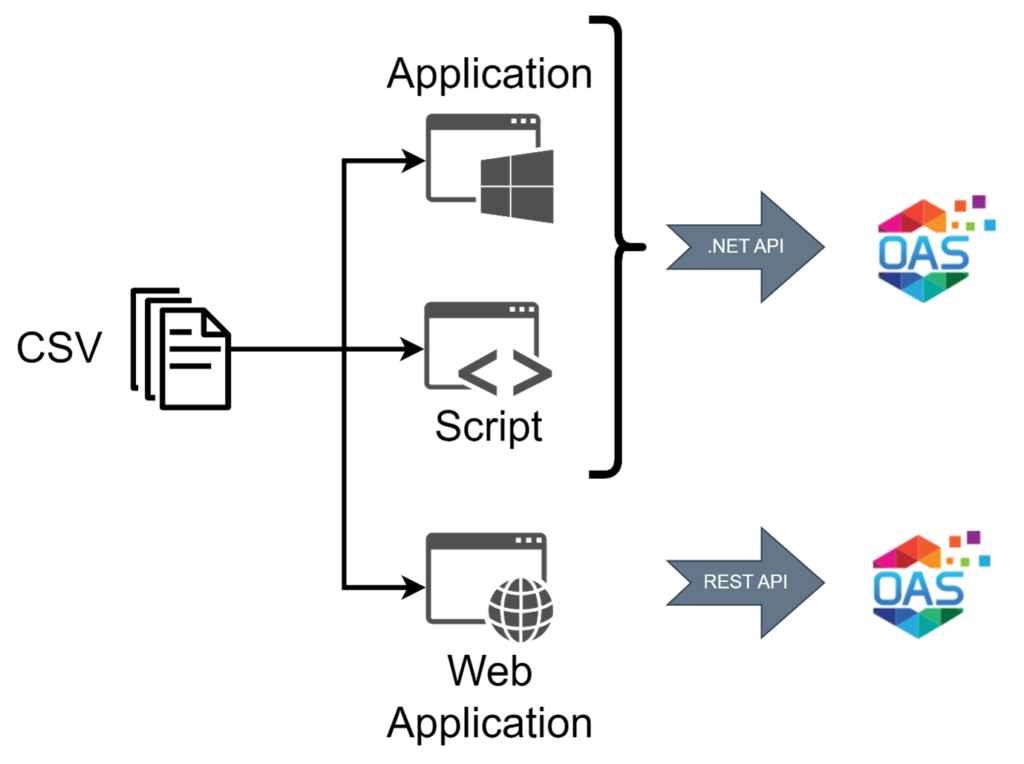

Automate the process of importing CSV files by using the OAS .NET or REST API.

This option is great if you have an existing ability to generate CSV files, or you simply prefer to have a staged data pipeline, but rather than manually importing individual CSV files you can automatically feed them into OAS using an application or script that uses the OAS .NET or REST API.

Which method is best for me?

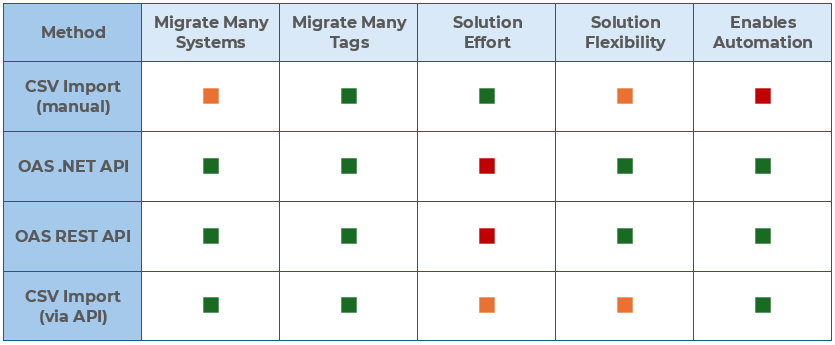

Choosing the right method will depend on the complexity of your legacy systems, requirements for the new systems and the capabilities available in your technical teams.

Manual and text file methods will inherently require less skills, but will be prone to errors and inefficiency when dealing with many systems and frequent updates.

The OAS API driven methods on the other hand are more complex and therefore require development effort and specific technical skills, but the automation potential and repeatability of the process are strong benefits.

The following table summarizes some of the strengths and weaknesses of each method.

From Legacy to the Future

By using OAS and the configuration interfaces we explored, you are on the right path for migrating from a legacy system to a modern enterprise automation platform.

Here are some tips to help you move towards a successful outcome:

- Think about the business goals and users first before rushing into a technical solution.

- Moving away from a legacy system is a slow process and can take many months. Often new systems need to run in parallel to the legacy system. Invest in automation early and use the configuration APIs to synchronize the data between your legacy system and OAS.

- When migrating data, don’t be scared to organize your tags into a more suitable structure. OAS supports creating nested tag groups without impacting the way data is moved from your device into OAS.

💡 More information: https://openautomationsoftware.com/knowledge-base/getting-started-tags/🔗 - You don’t have to put everything onto one server or OAS instance, there are many supported networking and redundancy architectures. The benefit of OAS is that you can also improve your security posture and operational resilience.

💡 More information: https://openautomationsoftware.com/iiot-network/🔗