Goals

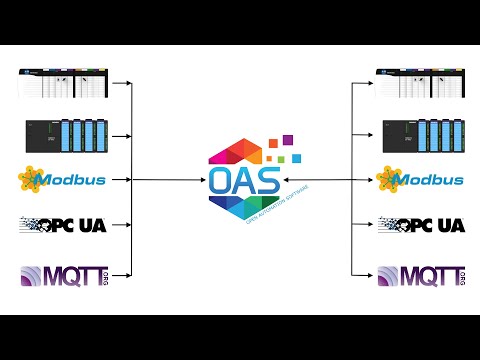

To automate and manage machine to machine transmission of data within an enterprise network or even over the internet.

Supported Data Sources

- Allen Bradley: ControlLogix, CompactLogix, GuardLogix, Micro800

- AB Classic: MicroLogix, SLC 500, PLC-5

- Siemens: S7-200, S7-300, S7-400, S7-1200, S7-1500

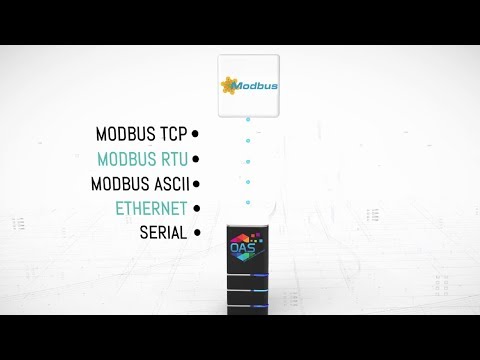

- Modbus: Modbus TCP, Modbus RTU, and Modbus ASCII

- MTConnect

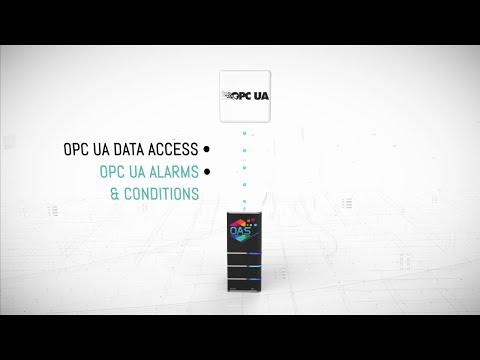

- OPC / OPC UA

- OPTO

- MQTT

- Amazon AWS IoT Gateway

- Databases: SQL Server, Oracle, MS Access, mySQL, PostgreSQL, Cassandra, MariaDB, SQLite, InfluxDB, MongoDB

- Custom Applications: .NET, or any other environment that can send JSON over HTTP to our REST API

- Proprietary Data Sources or Protocols: supported with our Universal Driver Interface (UDI)

OAS Components Used

This example Use Case utilizes the following OAS Platform Components and can be deployed in many different configurations to achieve the best performance and reliability:

OAS Universal Data Connector

OAS Universal Data Connector- Data Historian

- Allen Bradley Connector

- Siemens Connector

- Modbus Connector

- OPTO Connector

- OPC UA Connector

- OPC Client Connector

- Data Route

- OAS Recipe

- Excel Connector Connector

- Azure IoT Data Hub Connector

- AWS IoT Gateway Connector

- MQTT Connector

- .NET Data Connector

- REST API

Supported Data Destinations

- Azure IoT Hub and Azure IoT Edge

- Allen Bradley: ControlLogix, CompactLogix, GuardLogix, Micro800

- AB Classic: MicroLogix, SLC 500, PLC-5

- Siemens: S7-200, S7-300, S7-400, S7-1200, S7-1500

- Modbus: Modbus TCP, Modbus RTU, and Modbus ASCII

- MTConnect

- OPC Clients

- OPTO

- MQTT

- Databases: SQL Server, Oracle, MS Access, mySQL, PostgreSQL, Cassandra, MariaDB, SQLite, InfluxDB, MongoDB

- Microsoft Excel

- Custom Applications: .NET, or any other environment that can send JSON over HTTP to our REST API

- Proprietary Data Destinations or Protocols: supported with our Universal Driver Interface (UDI)

Solution Description

The Data Route feature of the OAS Platform enables automated data transfer between any data source and destination supported by OAS. Additionally, the .NET Data Connector and Universal Driver Interface extend this capability to virtually any data source or protocol. Data points are mapped to Tags within the OAS service and are then available to all components of the OAS Platform. Using the OAS Data Route, tag values are mapped to other tags connected to the Data Destination. These destination tags can be on the same device as the data source or other devices on the network or even over the internet. The transfer of data can be configured to update every time the value changes, update based on dead-band or at a specified rate.

M2M IOT with Data Route

Once the data is within the OAS server, it can also be manipulated with the powerful Calculation Engine before it is transmitted to the destination. Also, if the destination is a database, high-speed data logging can be achieved using the Data Historian feature which incorporates a store-and-forward feature. This allows for data buffering so if the destination can not be reached, data will be stored in the OAS server and forwarded when communications are reestablished.

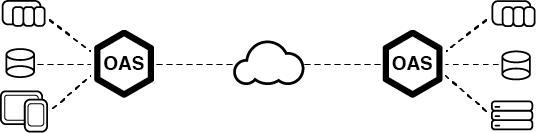

When deploying an enterprise IoT solution with the OAS Platform where multiple physical locations are involved, you can also choose to deploy an instance of the OAS Universal Data Connector on each location’s network, ensuring all data points are captured and transferred to the destination using secure communications.

Data Route Features

Data Transfer Types:

- Continuous: Transfer data every time the Tag Value changes.

- Dead-band: Transfer data when the tag change exceed the preset dead-band.

- Specified Rate: Transfer data a a specified rated regardless of value change.

Built in Calculation Engine:

use the OAS calculation engine to perform complex calculations on multiple items, process and interpret source data, then transfer the result to the destination system.

Automated Setup:

- One Click Allen Bradley

Tags can be automatically setup by using the One Click Allen Bradley feature that reads all variables from a controller file and creates tags based on the variables and data types found. - One Click OPC and OPC UA

Tags can be automatically setup by using the One Click OPC feature that browses OPC and OPC UA Servers automatically and creates tags based on the OPC Items defined in the OPC Server - One Click Database

Data Logging Groups can be automatically setup by using the One Click Database feature that browses Open Automation Software Tags automatically and creates data logging