Platform Components

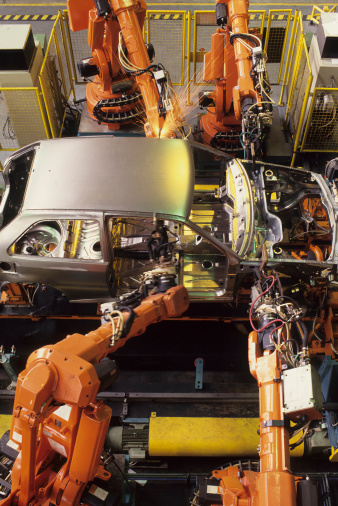

IoT in Industrial Robotics

What if industrial robots communicate with each other in the cloud? It is possible by integrating IoT with industrial robots. The Internet of Robotic Things (IoRT) allows industries to use several robots for handling particular tasks and watch the statistics of each machine on a dedicated dashboard. By combining IoT with robotics, businesses can achieve industrial automation which, in turn, improves overall efficiency and cohesiveness.

Both, IoT devices and robots use sensors to understand their environment, process a large volume of data, and respond accordingly. However, unlike robots, IoT applications handle well-defined tasks. And that’s why IoT can make robots more productive and efficient. By integrating IoT with industrial robots, it has become possible to continuously monitor and measure the performance of the robot for each cycle. Industries may either use a smart system/device for monitoring the robot, or the IoT-enabled robot can by itself collect all data of its sensors. An intelligent robot can either store or transmit live data.

IoT gives remote access so that companies can monitor performance-related or unexpected issues remotely. Remote and secure access to robot controllers and connected equipment gives instant access to engineers’ expert knowledge from anywhere. This also provides a report on the condition and performance of robots to ensure a faster reaction time, higher efficiency, and better preparation for on-site service support.

IoT & Robotics for Work Automation

The robotics industry is expected to excel by implementing the IIoT. IoT and related technologies allow plant managers to assess the performance of multiple robots across numerous business locations. Using IoT in robotic automation improves productivity, increases the lifespan of robots, and optimizes maintenance. Most industrial robots can be connected to IoT to open up a world of new opportunities for predictive, proactive and immediate support. IIoT provides connected devices and sensors that allow companies and their employees to do things they wouldn’t even have dreamed of prior.

At OAS, we help companies to ensure zero downtime. Remote access to robots prevents the robot’s unplanned downtime due to unexpected failure. It also gives notifications when you need to schedule your maintenance trip and be ahead of it. The IIoT-ready robots allow business managers to oversee production at a plant.