Summary:

- AI improves manufacturing efficiency through smarter, data-driven decisions and real-time process adjustments.

- Predictive analytics helps prevent equipment failures, fine-tune maintenance, and cut down on unplanned downtime.

- AI-powered robotics and machine vision enhance accuracy, safety, and flexibility in sorting, control, and custom production.

- Real-time data and a solid infrastructure are key to making AI work effectively on the factory floor.

- As AI adoption grows, manufacturers need strong data integration tools to stay competitive and keep innovating.

AI in manufacturing is no longer a vision of the future; It’s a driving force behind today’s most advanced and efficient production environments. From streamlining operations to uncovering new opportunities for innovation, artificial intelligence is transforming how manufacturers approach everything from maintenance to quality control.

This shift isn’t just about adopting new tools, it’s about leveraging data in smarter ways to make faster, more informed decisions. As AI continues to evolve, its impact on the manufacturing industry is becoming not only more powerful but also more practical.

In the sections ahead, we’ll explore how AI is shaping the future of manufacturing and why a strong data foundation is essential to making it work.

How is AI Used in Manufacturing?

AI in manufacturing is changing how production works altogether. Instead of relying on rigid programming, AI systems can learn from data, adapt to new conditions, and make smart decisions in real time. That means fewer manual adjustments and more efficient processes from start to finish.

With technologies like machine learning (ML) and computer vision, manufacturers are tackling tasks that used to be time-consuming or prone to error. AI tools are making it easier for teams to identify defects, fine-tune production flows, and achieve better results with less manual effort.

Turning Data Into Action

One of the biggest benefits of AI in the manufacturing industry is its ability to make sense of all the data coming from machines and sensors. What used to be just raw numbers can now fuel real-time insights, like predicting when a part might fail or spotting ways to improve output. It’s about turning information into smarter decisions.

How AI Helps Keep Production Running Smoothly

Predicting Problems Before They Happen

One of the most practical and impactful AI applications in manufacturing is predictive analytics.

By analyzing data from sensors, machines, and control systems, AI can detect patterns and spot potential issues long before they become costly problems. This gives manufacturers the ability to plan maintenance proactively, avoiding surprise breakdowns and keeping operations running on schedule.

Reducing Downtime with Smarter Maintenance

Traditionally, maintenance has followed either a reactive model (fix it when it breaks) or a scheduled model (service it whether it needs it or not). Predictive analytics changes that.

With AI, manufacturers can determine exactly when maintenance is needed based on real-time usage and performance data. This approach helps reduce unnecessary downtime and saves on maintenance costs.

Catching the Subtle Signs of Trouble

AI doesn’t need alarms to know something’s off. It can pick up on small changes, like unusual vibrations or heat patterns, that may signal an issue in the making. These early warnings help teams fix problems before they turn into expensive delays.

Feeding AI the Right Data, in Real Time

For predictive analytics to deliver results, it depends on fast, accurate, and consistent data. That’s why real-time connectivity platforms are so important. They ensure AI systems have the up-to-date information they need to keep everything running smoothly.

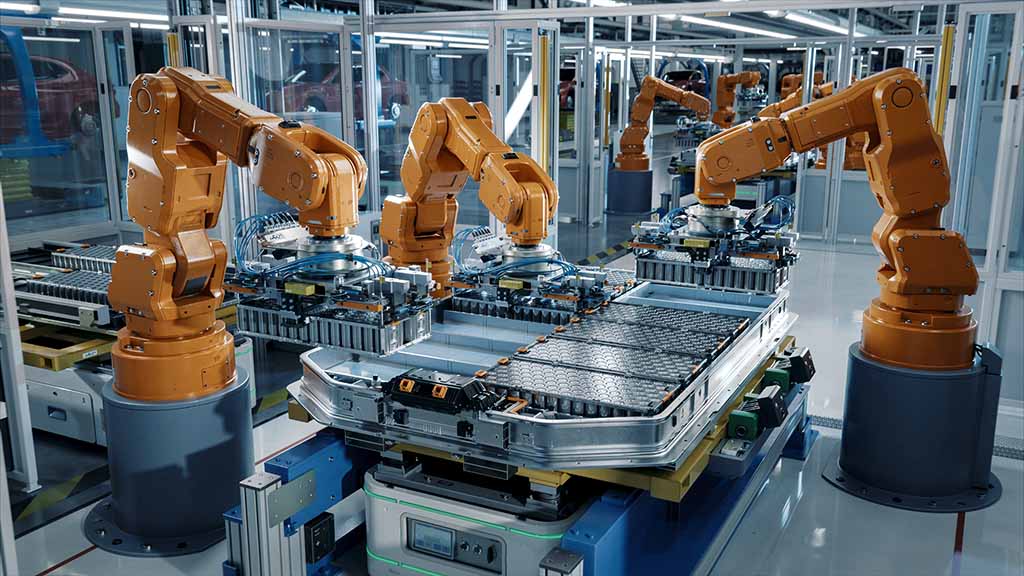

Enhancing Accuracy and Safety with Robotics

Robotics has long played a role in manufacturing, but AI is taking it to a new level. Instead of just repeating tasks, today’s robots interpret their environment, adapt to changing inputs, and collaborate more safely with human workers.

With the help of AI and machine vision, robots can now make decisions in real time, improving both accuracy and responsiveness on the production floor.

Modern collaborative robots, or cobots, are built to safely share space with human workers. Thanks to AI in manufacturing, they can slow down, stop, or change direction when someone’s nearby, and even tweak their tasks based on real-time input. It’s a smarter, safer way to boost productivity and let people and machines work side by side.

Real World Examples

These AI in manufacturing examples show just how flexible and useful this technology can be on the factory floor.

Smarter Sorting and Classification

AI systems that use machine vision are now handling tasks like sorting parts by size, color, shape, or surface details. These systems reduce errors and speed up material handling, which helps keep production lines efficient and accurate.

Fine-Tuning Processes in Real Time

Another valuable AI use case in manufacturing involves adjusting process parameters like temperature, pressure, or mixing times based on real-time data.

This kind of automation helps maintain consistency and quality, especially in industries like food and beverage, chemicals, and plastics.

Handling Custom Orders with Ease

AI helps production lines adapt to product variations without needing a full system overhaul. Smart robots and decision-making tools can adjust to different product specs as they go, making it easier to manage personalized orders efficiently.

Looking Ahead: AI-Driven Innovation and Future Trends

AI in manufacturing is quickly evolving, with the focus shifting toward smarter, more connected systems that can adapt and optimize on their own. The goal isn’t just efficiency, it’s flexibility and long-term resilience.

According to McKinsey’s 2025 survey, AI adoption continues to grow, with 78% of organizations now using it in at least one area of their business, up from 72% last year. This significant increase underscores AI’s growing role in driving operational efficiency and innovation.

To stay competitive, manufacturers will need strong data infrastructure and seamless system integration. With the right foundation, AI can continue to deliver value and drive progress well into the future.

Where Innovation Meets Implementation

If you’re looking to make AI truly work for your manufacturing operations, Open Automation Software can help. With powerful data integration tools and real-time connectivity across devices and platforms, OAS provides the foundation needed to support AI-driven innovation from the ground up.

Ready to explore what that looks like in your facility? Learn more about OAS and request a demo to see our products in action.